Aust J Crop Sci. 19(04):408-415 (2025) | ISSN:1835-2707

https://doi.org/10.21475/ajcs.25.19.04.p286

Damage to eucalyptus stumps due to machinery and positioning of tree bundles during timber harvesting

Joyce Luize Caetano de Oliveira, Felipe Martins de Oliveira, Antonio Ozenilto de Sousa Lima, Eduardo da Silva Lopes*

Department of Forestry Engineering, Midwestern State University, Irati, Brazil

*Corresponding author: Eduardo da Silva Lopes

Abstract: The positioning of tree bundles within the forest stand can influence the movement of machinery during timber harvesting, causing damage to the stumps and reducing sprouting during stump management. This study aimed to assess the damage caused by timber harvesting machinery to the remaining stumps in planted eucalyptus forests based on the angle of tree bundle arrangement. The research was conducted at a forestry company in the southern region of São Paulo state, in a hybrid stand of 9-year-old Eucalyptus grandis × Eucalyptus urophylla, in the first rotation or cutting cycle, using a feller buncher and skidder. Damage to the stumps caused by machines based on tree bundle angles of 17º and 45º was assessed through measurements of the stumps after timber harvesting. The following quality parameters were evaluated: height, soil and/or forest residue coverage, tearing, peeling, and shearing. The data were analysed using a completely randomized design, with two treatments and eight repetitions composed of sub-plots with 20 stumps, compared using Student's t-test at a 5% probability level. Results showed that, at both tree bundle angles, the stump height was within the reference value of 10 to 15 cm. Similarities in physical damage to the stumps were observed with tree bundles arranged at both angles. The highest occurrence of damage was shearing, with 35.1% of stumps affected at the 17º angle and 19.2% at the 45º angle. The 45º angle of the bundled trees in the moment of timber harvesting at the flat terrain conditions facilitated the machines movements, reducing the stump damage and improving the shoot development and sprouting rates for the stand under the stump management regime.

Keywords: Timber harvesting; physical damage; stump’s quality; operational planning; production.

Abbreviations: cm_centimeter, p_probability level, mm_millimeters, m_meters; m2_squate meters, m3_cubic meters, º_degrees, %_percentage, t_student's test.

Introduction

Commercial eucalyptus plantations in Brazil are characterized by high productivity, where any reduction in costs and improvements in quality within the production process can lead to significant gains and greater competitiveness for forestry companies (Gonçalves et al., 2014; McEwan et al., 2020; Santos and Reichert, 2022). Within the production process of planted forests, timber harvesting operations are notable, representing over 50% of the cost of timber delivered to the industry. Additionally, timber harvesting is influenced by various variables that impact productivity and the quality of forestry operations, including terrain slope, species, diameter and volume of trees, planting spacing, forest management model, type of equipment, wood assortments, and aspects of operational planning (Machado, 2014; Bassoli et al., 2020).

In recent years, the high demand for wood consumed by forest-based industries has required the adoption of fully mechanized wood harvesting systems, using heavy machinery with high production capacity, resulting in high traffic intensity within the forests. This situation may cause several negative impacts on the physical properties of the soil and the remaining tree trunks, affecting the regeneration process and conduction of sprouting, with a consequent reduction in wood production in the next forest rotation (Miyajima et al., 2019; Rodrigues et al., 2022). Nowadays, the rise in machinery traffic during cutting and extraction operations, combined with the large volumes of wood handled by forest companies, often results in various types of mechanical damage to the remaining stumps, such as crushing, shearing, and abrasion, which can impair shoot development and reduce timber production (Payá et al., 2019).

For this reason, an efficient operational planning of timber harvesting is crucial for the success of the forest management, involving aspects related to macro-planning, such as: dimensioning and allocation of resources and the sequencing of timber harvesting operations (Munis et al., 2023), as well as aspects related to micro-planning, such as: direction of felling and stacking of timber, angle in the formation of tree bundles, distance and direction of timber extraction, and characteristics of timber storage locations (Machado and Lopes, 2014; Miyajima et al., 2019).

Several studies have evaluated the productivity and production costs of feller bunchers and skidders within the full-tree timber harvesting system concerning variables extraction distance, terrain slope, types of machines and wheels, forest characteristics, forest management regime, etc. (Santos et al., 2013; Lopes et al., 2014; Simões et al., 2014; Miyajima et al., 2019). However, despite the consolidated management process adopted by many Brazilian forestry companies to improve the initiation of sprouting, justified by the reduction of costs for the formation of future forests (Gonçalves et al., 2014), there is still a lack of studies aimed at identifying the effects of machine operating procedures in the timber harvesting, especially related to the angulation of tree bunches, damage to remaining stumps and on the development of sprouts. Schwegman et al. (2018) reported that the increase in the mechanization of timber harvesting operations, along with other impacts occurring in the forest, must consider the potential damage to remaining stumps and the subsequent capacity for regeneration through stump management. Some authors (Klein et al., 1997; Stape, 1997) reported that the main aspects influencing the quality and productivity of eucalyptus stump regrowth include cutting height, coverage of stumps by soil and/or forest residues, and physical damage to the stumps such as peeling, shearing, and cracking. Often, such damage is caused by heavy machinery movement during forestry operations.

Additionally, damage to the stumps can be attributed to a combination of factors associated with timber harvesting operations, particularly machinery movement and contact between trees and parts of the stumps during tree removal. Therefore, identifying potential damage to remaining stumps caused by machinery will help managers to adopt the best strategies for planning and executing operations, leading to improvements in machinery productivity and sustainability of forest production. Therefore, the objective of this study was to evaluate the effect of the angle of tree bundles on damage to the remaining stumps due to the movement of timber harvesting machinery in a eucalyptus stand under coppice management.

Results

Stump height

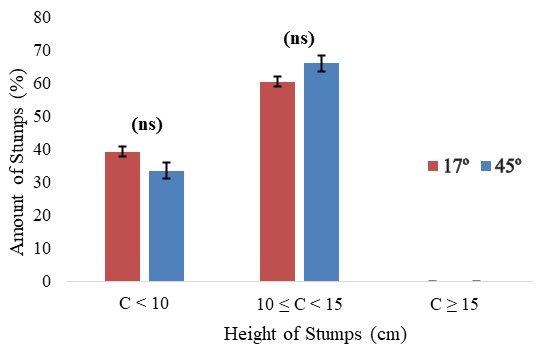

The average heights of the tree stumps in the forest stand after felling and stacking the tree bundles by the feller buncher at angles of 17º and 45º were 10.0 and 9.8 cm, respectively, with no significant difference between treatments according to the Student's t-test (p ≤ 0.05). Most of the stumps were within the reference value between 10 and 15 cm in height determined by the forestry company, which is ideal for the formation of a greater number of buds and, consequently, for an increase in the sprouting rate (Figure 1). At the 17º angle of the bundles, 60.6% of the stumps were between 10 and 15 cm in height, while at the 45º angle, this figure totalled

Figure 1. Average height of stumps caused by timber harvesting in due to the arrangement of tree bundles. (ns) = not significant; and (*) = significant.

66.3%. The strains below 10 cm in height totalled 39.4% and 33.7% at angles of 17º and 45º, respectively, highlighting that no strains with heights greater than 15 cm were found, demonstrating the efficient quality of the operation concerning this requirement.

Physical damage to stumps

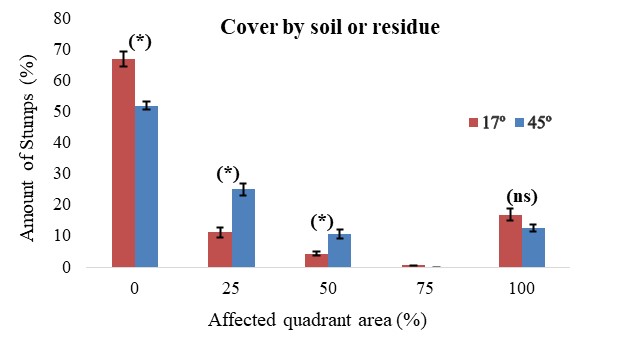

The physical damages caused to the stumps after the traffic of the timber harvesting machines due to the arrangement of the tree bundles at angles of 17º and 45º are shown in Figure 2. The coverage of the stumps by soil and/or residues from timber harvesting showed that on average, 22.3% and 24.0% of the stumps were affected in situations of tree bundle angles at 17º and 45º, respectively, with a statistical difference by Student's t-test (p ≤ 0.05) (Figure 2a). It is noted that most stumps did not have their surface covered by soil or forest residues from timber harvesting, regardless of the angle of the tree bundles. At beam angles of 17º and 45º, it was observed that 16.9% and 12.5% of the stumps, respectively, had their surface completely covered by soil and/or residues (100%), which can be considered a high value and cause significant failures in the sprouting rate of the stumps due to the reduction in light incidence, compromising the regeneration and future productive capacity of the forest stand.

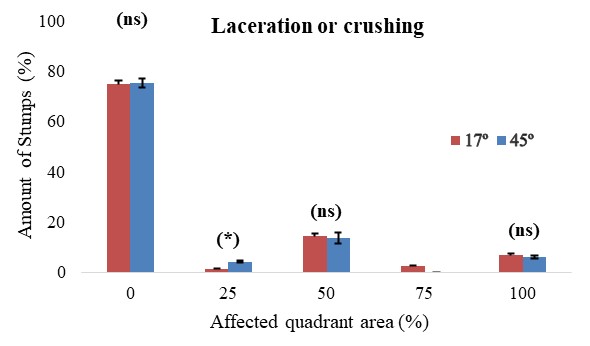

Regarding the tearing or crushing of the stumps caused by the wheels during the traffic of the feller buncher and skidder in the timber harvesting operations (Figure 2b), it was observed that, in general, 16.2% and 14.2% of the stumps were damaged when the tree bundles were angled at 17º and 45º, respectively (Student's t-test; p ≤ 0.05) in the quadrant with 25% of the affected area. It was possible to verify that, 6.9% and 6.3% of the stumps presented areas completely damaged by the wheels of the machines, caused especially by the maneuvers performed by the skidder when loading the tree bundles arranged at angles of 17º and 45º, respectively.

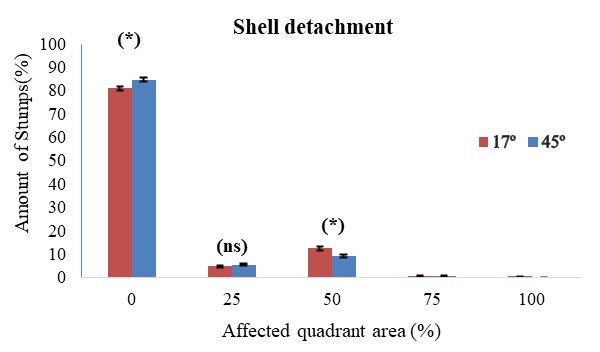

The detachment of the bark from the tree stumps can be considered a physical damage caused by the feller buncher head at the time of felling and by the skidder wheels when dragging the trees (Figure 2c). In general, it was found that 8.9% and 6.5% of the stumps were damaged when the tree bundles were arranged at angles of 17º and 45º, respectively (Student's t-test; p < 0.05) in

Figure 2. Physical damage to stumps caused by timber harvesting machines due to the arrangement of tree bundles. (ns) = not significant; and (*) = significant.

the quadrant with 0 and 50% of the affected areas. When analyzing both angles of the tree bundles, we observed that above 80% of the stumps had no occurrence of bark detachment, with 81.1% at the 17º angle and 84.9% at the 45º angle. The occurrences of bark detachment remained between 25 and 50% of the area of the strains, totalling 17.6% and 15.1% of the strains affected at angles of 17º and 45º, respectively.

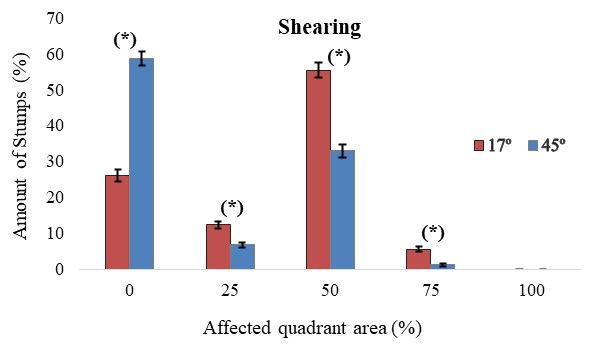

A high rate of damaged and shearing vines was observed by the feller buncher cutting head after felling the trees (Figure 2d). Overall, 35.1% of the vines were damaged when the bundles were arranged at an angle of 17º, while 19.2% of the vines were damaged at an angle of 45º in all quadrant situations (Student's t-test; p ≤ 0.05). Analysis of the total affected area of the vines showed a greater occurrence of damage in the 50% quadrant, with 55.6% and 33.1% of the vines affected at the 17º and 45º angles of the bundles, respectively.

Discussion

The height of stumps in eucalyptus plantations is an important quality parameter to be considered in timber harvesting operations, as it has a direct relationship with the capacity for sprout emission when adopting the stump management regime. Additionally, height is a factor that should be considered in planning, as it can be affected by the types of machinery and different operational procedures used. Therefore, cutting trees at a lower height can improve wood utilization and reduce damage to the machinery wheels. On the other hand, it results in fewer buds on the stumps and a reduction in sprouting capacity.

The results of this study showed that the height of the stumps in both treatments was within the quality standards expected by the company. This can be attributed to the flat terrain characteristics, which facilitated machinery movement and improved operator visibility during the positioning of the head for tree

cutting. Despite the similarity in stump heights when felling and stacking the trees at both angles, there was better quality observed in the stacking operation at the 45º angle. It is important to note that there is no direct relationship between stump height and the bundle angles, as the bundling of the trees is an operational procedure carried out after the felling of the trees.

Reboleto et al. (2016) analyzed the quality of eucalyptus tree cutting at different terrain slopes and found that in up to 20º of inclination, stumps remained within the recommended height, with a maximum stump height of 10 cm. In slopes between 20º and 30º, the average stump height reached 12.5 cm. Luz et al. (2018) stated that taller stumps are harder to cover with residual biomass from timber harvesting, contributing to a higher number of buds and an increased sprouting rate, while survival decreases for stumps below 10 cm. Berude et al. (2021), evaluated the quality parameters in cutting with a harvester and extraction with a forwarder in pine stands subjected to two thinning models. They observed that approximately 90% of the stump heights ranged between 10 and 15 cm. It is also important to highlight that stump height is a controversial factor from the perspective of sprout management quality. According to some authors (Baena et al., 1983; Luz et al., 2018), higher stump heights promote sprouting. However, a higher number of sprouts in the initial phase also increases competition among them, negatively impacting the average diameter. On the other hand, stumps with heights above the company's established limit, resulted in wood losses, hindering the skidding operation, and increase the chances of machine’s wheel damage and workplace accidents.

The physical damage to stumps showed that these issues have a direct relationship with timber harvesting operations, mainly due to the feller buncher head during tree positioning and cutting, as well as the skidder wheels and the trees themselves during timber skidding. Regarding the presence of soil and/or residues on the stumps, we observed that the number of stumps with

Table 1. Illustration of the timber harvesting system and technical specifications of the machines evaluated in the study.

Timber harvesting System |

Activity and machine studied | Technical specifications | |

|---|---|---|---|

|

Felling | Fellner buncher

|

Tigercat model 845D: operational weight of 25,900 kg, engine power of 212 kW, equipped with tracked undercarriage and a head weighing 2,245 kg, cutting disc of 50 mm, rotation of 1,500 rpm, and a maximum cutting radius of 8.05 m. |

| Extraction | Skidder

|

Tigercat model 635D: operational weight of 21,430 kg, engine power of 194 kW, equipped with a wheeled undercarriage and a front grapple with a maximum opening of 3.81 m. | |

50% or more of their surface covered was similar between both beam angles, with 21.9% and 23.1% of the stumps covered in angles of 17° and 45°, respectively. The presence of soil and/or residues on the stumps in both angles occurred due to cutting the trees close to ground level, leading to the accumulation of soil and sawdust. In studies conducted on Eucalyptus grandis plantations, Klein et al. (1997) found that the presence of coverage on stumps by branches, leaves, bark, wood, or soil can impair sprouting due to reduced light incidence. The authors also found that stumps free of harvest residues and soil at a height of 10 cm had a 95.4% sprouting survival rate.

The occurrence of stump tearing or crushing is a physical damage that has a direct relationship with machinery movement, primarily affected by the wheels during tree cutting and timber extraction operations. The results revealed a similarity in damaged stumps (25.0% and 24.4%) for the beam angles of 17° and 45°, respectively, with affected surfaces having areas above 25%. It is important to highlight that the beams in both angles were favorably aligned with the planting rows and with the bases of the trees oriented towards the road, facilitating stacking by the feller buncher and subsequent loading and skidding by the skidder. This setup therefore favored machine maneuverability and reduced wheel passage over the stumps. This situation contrasts with tree stacking at a 90° angle to the planting rows and the road, which occurs in some operational scenarios, where more maneuvering is required during loading and machine turning during skidding (Miyajima et al., 2019), potentially resulting in greater impact from the wheels on the stumps. Mechanical damage to the stumps caused by machine wheels should be constantly monitored when applying new operational procedures in timber harvesting, as such damage, regardless of the affected stump area, may impact the sprouting capacity and survival rate, which is influenced by the number of sprouts per stump (Souza et al., 2012).

Bark peeling on stumps is physical damage caused by the feller buncher head during cutting and by the skidder wheels during tree skidding. The results showed a similarity in this damage between the tree beam angles, which can be considered high and detrimental to the number of buds and stump sprouting, potentially reducing timber production in the next rotation of the stand. It is important to note that, among timber harvesting operations, skidding is the main contributor to bark peeling, as both the machine wheels and the tree bundle come into contact with the sides of the stumps, causing the peeling. However, this physical damage can be minimized through improvements in planting alignment or spacing to avoid stump damage and increase regeneration capacity (Ferrari et al., 2005), as well as operational planning improvements by concentrating machine traffic during tree skidding. Klein et al. (1997) reported that partial or total bark peeling reduces sprouting possibilities, delaying the bud emergence, and diminishes the height of dominant sprouts.

Shearing of stumps is typically caused by the cutting head of the feller buncher during tree felling. When analyzing the occurrence of this damage across all quadrants of the stump, the 45º angle of the tree beams favored better positioning of the machine’s head during wood cutting compared to the 17º angle, which resulted in 73.8% of the stumps being partially damaged. It is important to highlight that the high percentage of damaged stumps can be attributed to the dullness of the cutting teeth on the machine’s head, as well as the breakage of the cutting teeth during operation. Furthermore, difficulties in achieving a quality cut were observed due to the

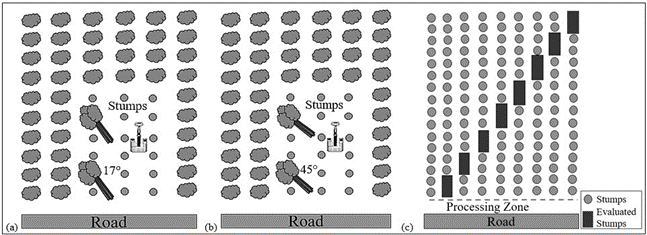

Table 2. Variables adopted in the assessment of damage to stumps.

| Variables | Description | |

|---|---|---|

| Reference stump |  |

Stump with standard quality, at the recommended height and free of physical damage. |

| Stump height |  |

Stump with a lower height than recommended. |

| Soil cover and/or forest residues |  |

Partial or total coverage of the stump by soil and/or wood harvesting residues (leaves, bark and branches), caused by wood harvesting operations. |

| Tearing |  |

Crushing of the stump, caused by the wheels of the machines during wood harvesting operations. |

| Shell detachment |  |

Partial or total removal or removal of the bark, caused by the cutting head and wheels of the machines during timber harvesting operations. |

| Shearing |  |

Wear of the stump caused by the machine's cutting head when felling the trees. |

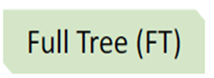

Figure 3. Arrangement angle of tree bundles in treatments at 17º (a) and 45º (b); procedure for sampling damage to the stumps (c).

accumulation of sawdust and soil inside the cutting head, which interfered with the rotation of the disc during cutting and, consequently, negatively impacted stump quality. In this regard, regular maintenance of the cutting discs is crucial to keep the equipment in good working condition, as Reboleto et al. (2016) noted that shearing of stumps is a physical damage that directly affects sprout emission, damages logs, and results in losses of high-value wood at the base of the tree.

Materials and Methods

Study area

The study was conducted in the operational areas of a forestry company located in the southern region of São Paulo, Brazil. The climate of the region is temperate (cfa), with an average annual precipitation of 1,313 mm and an average annual temperature of 19.5°C. The terrain is classified as flat-to-undulating, and the soil is dark red latosol with a clayey texture. Data were collected during timber harvesting operations in a hybrid plantation of Eucalyptus grandis × Eucalyptus urophylla, managed under a clear-cutting regime in its first rotation, which correspond to the first cutting cycle of the forest stand; age of plantation (9 years); planting space (3.0 x 2.0 m) and average trees volume (0.37 m3/tree). The timber harvesting operations aimed to preserve the integrity of the stumps for the establishment of new stands through sprout management (stump management), with the timber destined to produce pulp and paper.

The timber harvesting system evaluated was a full tree system, consisting of a feller buncher that performed the felling and bundling of trees into bunches within the forest. Subsequently, the trees were extracted using a skidder to the edge of the compartment, where they were then processed into logs by a harvester processor. The feller buncher felled trees in a strip consisting of four planting rows, accumulating an average of seven trees per felling cycle. The tree bundles stacked on the ground were formed by two operational cycles, averaging 14 trees for later extraction. The technical specifications of the machines evaluated in the study are presented in Table 1.

Sampling treatments and procedures

Two treatments concerning the angle of tree bundle arrangement within the compartment were evaluated

(Figure 3). In Treatment I (Figure 3a), the feller buncher performed felling and bundling with tree bundles arranged at an angle of 17º relative to the planting alignment, with the base of the trees facing the road to facilitate subsequent dragging of the timber. In Treatment II (Figure 3b), the feller buncher performed felling and bundling with tree bundles arranged at an angle of 45º relative to the planting alignment, with the base of the trees also facing the road. Subsequently, in both treatments, timber was extracted using a skidder over an average distance of 100 m. The study allocated two rectangular sample plots of 200 m (width) x 100 m (length), totalling an area of 4 hectares (40,000 m²) for each treatment.

After the completion of timber harvesting operations, eight sub-plots were systematically allocated for evaluating damage to stumps caused by machinery movement in both tree bundle angle treatments (Figure 3c). Each sub-plot consisted of 20 stumps, totalling 160 samples. Sub-plot 1 was placed at a minimum distance of 10 m from the edge of the compartment, corresponding to the first five rows of stumps, and was referred to as the processing zone. This procedure, known as the "edge effect," was adopted to avoid sampling stumps that might have been damaged by increased machinery movement during the placement of tree bundles at the edge of the compartment and the subsequent processing of the trees.

Stump damage

The damage to the tree stumps was assessed cumulatively, caused by the felling and stacking of trees by the feller buncher and by the skidder skidding of the tree bundles. Initially, the assessed tree stumps were subdivided into quadrants, aiming to determine the percentage of area affected by the damage, with a value of 25% being assigned to each part, which together represented the total percentage of the affected area. Five types of damage to the stumps were evaluated (Table 2). The height measurement was obtained directly using a tape measure, measuring from the soil surface and considering the highest side of the stumps. Stumps were classified as having a height between 10 and 15 cm. Other variables, such as soil and/or forest residue coverage, tearing, bark peeling, and shearing of the stumps, were assessed visually. The quadrants' areas were used as a reference to determine the percentage of the stump surface affected by damage, following the methods proposed by Klein et al. (1997) and Foelkel (2014). These studies suggest that these variables can impact the sprout index in eucalyptus plantations managed through stump management.

The experiment was evaluated using a completely randomized design (CRD). The F test (independent samples) was applied to test the homogeneity of variances within each angle of arrangement of the tree bundles. Then, the Student's t test was applied at the 5% probability level to compare the means of damage to the stumps between treatments.

Conclusion

After timber harvesting operations, most of the stumps in the forest stand, regardless of the tree bundle arrangement angle, had the expected height, which is favorable for producing a greater number of buds per stump and, consequently, increasing the sprouting rate. It is important to note that the angle of beam disposition does not have a direct relationship with stump height, as this arrangement is an operational procedure performed after the trees have been felled.

The angles of the tree beam disposition did not directly impact physical damage to the remaining stumps in the stand. Greater issues were observed concerning soil and forest residue coverage and stump shearing, attributed to the fact that tree cutting was performed close to ground level, leading to the accumulation of soil and sawdust, and the inadequacy of the cutter head's sharpening. The tree disposition at a 45° angle proved to be the most suitable procedure for flat terrain conditions, facilitating machine manoeuvrability during cutting and extraction and contributing to lower damage rates to stumps. Consequently, this results in better sprouting rates for the stand under the coppicing management regime.

Disclosure statement

The authors declare that there is no potential conflict of interest on this paper.

Acknowledgments

The authors thank the Brazilian forest company for their support during the data collection and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, Capes, Brasil by support funds – Finance Code 001.

References

Baena ES (1983) Efeitos de algumas práticas silviculturais na brotação de Eucalyptus saligna. Silvicultura. 8(32): 617-620.

Bassoli HM, Miyajima RH, Paludo V, Fenner PT (2020) Influência da largura da faixa de trabalho na operação de corte com feller buncher. Adv For Sci. 7(2): 1067-1072.

Berude LC, Fiedler NC, Lopes, ES, Rodrigues CK, Nadolny A, Pelissari AL (2021) Designing the mechanized first thinning in a pine stand: assessment of productivity, costs and tree damage. Int J Forest Eng. 32(3):1-8.

Ferrari MP, Ferreira CA, Silva HD (2005) Condução de plantios de Eucalyptus em sistema de talhadia. Colombo: Embrapa Florestas. Documentos, 104.

Foelkel C (2014) O problema dos tocos residuais das florestas plantadas de eucalipto. Eucalyptus Newsletter, n. 45.

Gonçalves JLM, Alvares CA, Behling M, Alves JM, Pizzi GT, Angeli A (2014) Produtividade de plantações de eucalipto manejadas nos sistemas de alto fuste e talhadia, em função de fatores edafoclimáticos. Sci For. 42(103): 411-419.

Klein JEM, Bortolas EP, Assis TF, Perrando ER (1997) Fatores operacionais que afetam a regeneração do Eucalyptus manejado por talhadia. Sci For. 11(30):10.

Lopes ES, Oliveira D, Sampietro JA (2014) Influence of wheeled types of a skidder on productivity and cost of the forest harvesting. Floresta. 44(1):53-62.

Luz DS, Freitas LC, Prates CJN, Barros APS (2018) Influência da altura e diâmetro das cepas na rebrota de Eucalyptus spp, Rev Inst Flor. 30(1): 47-51.

Machado CC (2014) Colheita florestal. 3 erd. Editora UFV, Viçosa.

Machado CC, Lopes ES (2014) Planejamento. In: Machado CC (ed). Colheita Florestal. 3rd edn. Editora UFV, Viçosa.

Mcewan A, Marchi E, Spinelli R, Brink M (2020) Past, present and future of industrial plantation forestry and implication on future timber harvesting technology. J For Res. 31(2): 339-351.

Miyajima RH, Britto PC, Tonin RP, Millani TM, Fenner PT (2019) Influência da disposição dos feixes de árvores em diferentes angulações na produtividade e custos de um sistema de árvores inteiras. Sci For. 47(124):655-666.

Munis RA, Almeida RO, Camargo DA, Silva RBG, Wojciechowski J, Simões D (2023) Tactical Forwarder Planning: A Data-Driven Approach for Timber Forwarding. Forests. 14(9): 1782.

Payá TIA, Lopes ES, Koehler HS, Muller MML, Cavalieri-Polizeli KMV, Silva, MKC (2019) Effect of traffic intensities of a directional feller and skidder on the compaction of a bruno nitisol. Árvore. 43(1): e430111.

Reboleto I, Fiedler NC, Berude LC, Juvanhol RS, Canzian WP, Carmo FCA (2016) Análise da qualidade do corte semimecanizado de eucalipto em diferentes declividades. ACSA. 12(3): 268-272.

Rodrigues MF, Rodrigues D, Pelledrini A, Pocojeski E (2022) Gradual increase in the intensity of machine traffic in timber harvesting: effects on soil composition and functionality. South For. 84(2): 148-163.

Santos KF, Reichert JM (2022) Best tillage practices for eucalyptus growth and productivity: A review on the Brazilian experience. RBCS. 46:e0210091.

Santos PHA, Souza AP, Marzano FLC, Minette LJ (2013) Produtividade e custos de extração de madeira de eucalipto. Árvore. 37(3):511-518.

Schwegman K, Little KM, Mcewan A, Ackerman AS (2018) Harvesting and extraction impacts on Eucalyptus grandis × E. urophylla coppicing potential and rotation-end volume in Zululand, South Africa. South For. 80(1):51-57.

Simões D, Fenner PT, Esperancini MST (2014) Produtividade e custos do fellerbuncher e Processador Florestal em povoamentos de eucalipto de primeiro corte. Cienc Florest. 24(3):621-630.

Souza FC, Reis GG, Reis MG (2012) Sobrevivência e Diâmetro de Plantas Intactas e Brotações de Clones de Eucalipto. FLORAM. 19(1):44-54.

Stape JL (1997). Planejamento global e normatização de procedimentos operacionais da talhadia simples em Eucalyptus. Série técnica IPEF. 11(30):51-62.