Aust J Crop Sci. 19(04):416-422 (2025) | ISSN:1835-2707

https://doi.org/10.21475/ajcs.25.19.04.p295

Response of different tomato hybrids for industrial processing (TCP 26116, CVR-8161, N-901, HM-7885 and CVR-9145) to irrigation management and planting seasons in Brazilian Savanna

Juliana Carla Carvalho dos Santos, José Alves Júnior*, Fabio Miguel Knap, Ricardo de Souza Bezerra, Fernando Rezende da Costa, Derblai Casaroli, Adão Wagner Pêgo Evangelista

School of Agronomy, Department of Soil and Water, Federal University of Goiás (UFG), Zip code 74.690.900, Goiania, Goiás, Brazil

*Corresponding author: José Alves Júnior

ORCID ID:

https://orcid.org/0000-0002-1187-3275

ORCID ID:

https://orcid.org/0000-0002-1187-3275

Abstract: The second most cultivated vegetable in the world is the tomato (Solanum lycopersicum), with Brazil being one of the countries with the largest production in the world, at 4 million tons annually. The socioeconomic importance is quite relevant on the national scene, since the state of Goiás is the largest national producer, responsible for 37% of total tomato production in 2021. The objective of this work was to evaluate the response of five tomato hybrids for industrial processing to the correct management of transparency and its influences on productivity and quality of production in two credit periods that are allowed in the state of Goiás, the 1st season: April to August (beginning of the dry season) and the 2nd season: June to September (end of the dry season). The trial was installed in an experimental arrangement in randomized blocks, in two periods, with five commercial hybrids (TCP 26116, CVR-8161, N-901, HM-7885 and CVR-9145) and four replications, totaling 20 experimental plots. Irrigation management was carried out following the recommendations of the Irrigatomate software. Soil sensors at three different depths were installed in the plots to monitor soil water content. Meteorological monitoring was carried out at the Irriplus 5000 station installed 50 meters from the experiment. The morphological characters were plant height, number of branches and number of leaves and at the end of the cycle, total productivity, commercial productivity, total soluble solids (brix degree) and savings yield were evaluated according to industry criteria. The data were tabulated with all assumptions of normality and linearity, then subjected to analysis of variance using the F test, using the SAS “Statistical Analysis System” program, with the means being compared with each other using the Tukey test, at a 5% error probability level. It was found that the five hybrids showed better responses in the first growing season. The CVR 8161 hybrid had higher total productivity, commercial productivity and higher pulp yield, in addition to the Brix degree being in the ideal range due to the proposed management. It is also concluded that the irrigation management used by the Irrigatomate software is independent of the hybrid.

Keywords: Solanum lycopersicum, tomato farming, irrigation, productivity.

Introduction

Tomato (Solanum lycopersicum) is the second most cultivated vegetable in the world. Brazil stands out as one of the main global producers, with an annual production of around 4 million tons (FAOSTAT, 2020; IBGE, 2022). In the national scenario, the socioeconomic importance of tomatoes is significant, especially in the state of Goiás (West Center of Brazil), which is the largest producer in the country, responsible for 37% of total production in 2021 (IBGE, 2022).

In the Cerrado region of Goiás, tomato cultivation for industry begins in February and continues until June, with harvesting occurring from June to October (Giordano and Silva, 2000). The success of tomato farming in the region is not only due to the advanced soil and climate conditions, but also to the continuous and successive implementation of technological innovations. These innovations include the use of genetic materials with greater production potential, semi-mechanized transplanting, mechanized harvesting, advanced supervisory management techniques, and climate monitoring stations, among others (Vilela et al., 2012). Despite being a practice widely incorporated into the tomato production system, irrigation can, paradoxically, limit plant development, affect productivity and fruit quality, and promote the occurrence of diseases, because irrigation is often carried out inadequately (Marouelli et al., 2012). Alves Jr. et al (2021) monitored fourteen industrial tomato production areas in Goiás state, and this diagnosis study revealed that there were errors in the irrigation management in all evaluated areas when analyzing the total water applied in the cycle. This is probably one of the reasons for low tomato productivity (85 t ha-1) in region.

In addition to climatic factors, it is essential to consider the genetic material (hybrids), since these comercial hybrids are adapted to different climates and regions, which directly influences productivity (Silva et al., 2020). Factors such as cycle length, concentration of soluble solids, fruit color, and resistance to pests and diseases must be considered when choosing the hybrid (Silva et al., 2006).

It is very difficult to find a hybrid that perfectly fits all the characteristics, which is why the main companies that sell tomato seeds for industrial processing have an average fruit mass standard that varies from 80 to 240g and an average cultivation cycle ranging from 90 to 120 days. In general, the majority have similar characteristics, however, the basic information about the hybrids that are of interest to the producer is very superficial, and can only be found on websites and informational folders of the companies that sell them and most of the time at events. field technicians. Even scientific studies that are considered recent are unable to provide a broad characterization of cultivated hybrids, since companies are always seeking to genetically improve the material, meaning that the turnover in the development of new hybrids is constant. This is undoubtedly one of the reasons why producers seek to acquire seedlings already in the transplantation phase from suitable nurseries, as they already minimize this stage and can thus guarantee the physiological and phytosanitary quality of this seedling (Jacinto et al., 2012; Madeira et al., 2016).

There is a lack of information on planning and recommending the most suitable hybrids for each time of year, with the aim of achieving greater productivity and better quality in production (Knapp, 2023). A preliminary study showed a difference in industrial tomato productivity at different seasons. The total productivity of tomato hybrid N-901 of when cultivated in Brazilian savana in begnning of dry season (autumn-winter) was 28.6% lower than the total productivity of cultivation in end of dry season (winter-spring) (Bezerra, 20219). And other studies have shown that proper irrigation management is crucial for enhancing tomato crop growth and development and optmizing water use (Knapp et al., 2024). Therefore, IrrigaTomate® is software that, in addition to advising the farmer on when and how much to irrigate, records the management effects carried out during the work throughout the cycle (Alves Jr. et al., 2022).

The objective of this study was to evaluate the response of five tomato hybrids for industrial processing (TCP 26116, CVR-8161, N-901, HM-7885 and CVR-9145) to correct irrigation management in two growing seasons (1st season: April to August) and (2nd season: June to September) in Abadia de Goiás-GO, Brazil, and their influences on productivity and production quality.

Results and discussion

Weather data

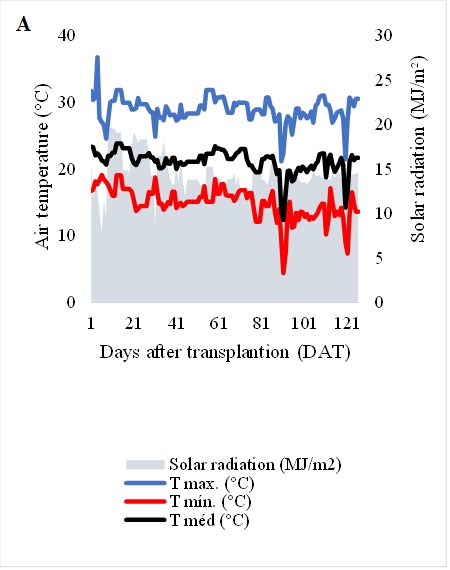

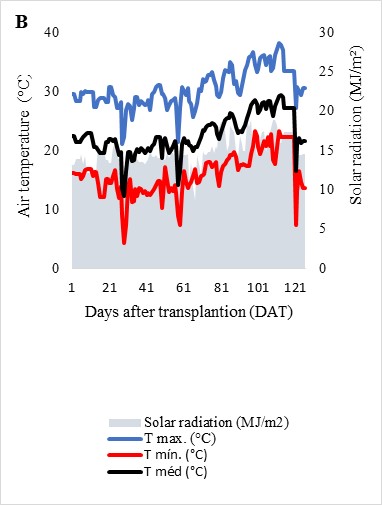

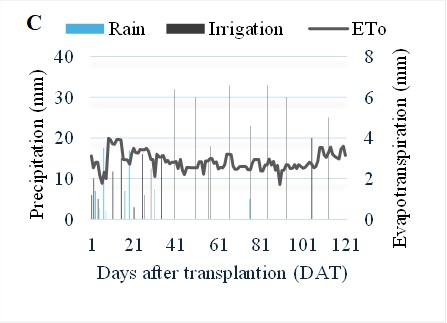

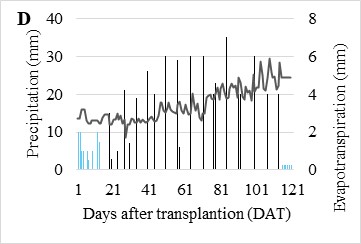

For the first planting season (126-day cycle), the average air temperature was 21.09 °C during the tomato cycle, ranging from 4.40 to 36.70 °C, with accumulated global solar radiation of 1,818.1 MJ m-2 cycle-1 (Figure 1A). The accumulated rainfall was 63.1 mm cycle-1 occurring in the first thirty days after planting, with intervals of up to eleven days, while irrigation was 360.3 mm cycle-1, and the average ETo was 2.87 mm day-1 (Figure 1C). For the second growing season (120-day cycle), an average air temperature of 22.7 °C was observed, ranging from 4.40 to 38.10 °C, the accumulated global solar radiation was 1,777.8 MJ m-2 (Figure 1B), accumulated rainfall of 61.2 mm, concentrated in the first fortnight after planting, and irrigation was 429.0 mm in the cycle, and the average ETo was 3.48 mm day-1 (Figure 1D).

Despite some peaks in air temperature, beyond the limits above 34 °C and below 10 °C (Pivetta et al., 2007 and Palaretti et al., 2012), the average air temperatures were observed within the limit considered suitable for crop growth and development (Filgueira, 2008). Although the recorded temperatures presented different behaviors throughout the two seasons, their variations were within the ideal range for tomato cultivation, which is capable of tolerating a temperature amplitude of 10 °C to 34 °C (Giordano et al., 2000).

The low precipitation levels at the beginning of the experiments, in both growing seasons, highlight the water shortage during the tomato harvest for industrial processing in the region. This highlights the importance of irrigation for the success of the crop in the Cerrado of Goiás (Marouelli et al., 2012). This lack of water is also reflected in global solar radiation, which showed a decreasing trend from the first to the second growing season.

Plant growth and fruits productivity

The average plant heights, number of leaves and branches per plant, of the six evaluations carried out (from transplanting the seedlings to the beginning of the reproductive period) in the first and second growing seasons for the five hybrids evaluated, are presented in Table 1.

In the first growing season, accelerated growth in plant height was observed from the fifth to sixth evaluation, when the plants were on average 26.8 to 43.1 cm tall, respectively. For the second growing season, accelerated growth occurred a little earlier, between the fourth and fifth evaluations, when the plants were 23.6 to 31.8 cm tall, respectively, significantly larger than the plants of the first cycle, which in the same period (fourth and fifth evaluations) were between 16.6 and 26.8 cm tall, respectively, evidencing a more favorable environment for growth in plant height, in the vegetative phase of the second planting compared to the first. One of the factors that can be observed is the greater water availability at this time, a fact that corroborates Zhang et al. (2020) who found a direct relationship between water availability and plant height, having a significant effect for greater plant heights. Despite the fact that, in the sixth evaluation (end of the vegetative phase), of both crops, the height of the plants was the same, with an average of 41.4 cm in height (Table 1).

For the first planting season, the tomato hybrids with the best performance in plant height were N901 and CVR8161, with 47.8 and 47.5 cm, respectively. However, CVR 8161 showed a significant drop in height from the first to the second season. While N901 maintained its

|

|

|---|---|

|

|

Figure 1. Global solar radiation (Rad), maximum temperature (Tmax), average temperature (Tmed), and minimum temperature (Tmin) of the air, precipitation/irrigation, and reference evapotranspiration daily for the 1st season (01/April to 10/August/2021) A and C; and 2nd season (02/June to 28/September/2021) B and D, for tomato cultivation in Abadia de Goiás-GO, Brazil.

prominence in height, in relation to the other hybrids, in both growing seasons. In the second growing season, the hybrids HM 7885 and TPC 26116 improved their performance, in relation to the first season, and equaled N901 in plant height, being the 3 best hybrids in height of this crop (Table 1). Although the hybrids CVR 8161 and N 901 presented plants with greater height in the first season, in relation to the other hybrids, this advantage did not have a positive impact on N 901, in the final production, being the hybrid with the lowest average for total and commercial productivity.

Bezerra et al. (2019) found that the total productivity of hybrid N 901 when cultivated in the first season was 28.6% lower than when cultivated in the second season. Regarding the number of leaves per plant, faster plant growth was also observed in the second crop, with a significant difference already observed from the second evaluation, while in the first crop the significant difference between the growth phases only occurred from the third evaluation (Table 1). And, unlike the height, in which the plants were equal at the end of the vegetative phase, for the number of leaves there was a

significant difference between the first and second cultivation cycles, with 45.5 and 57.1 leaves per plant, respectively. Among the hybrids, in the first crop, the highlight in the highest number of leaves per plant was for the hybrids CVR 9145, N901 and TPC26116, differing significantly from the hybrids with fewer leaves per plant CVR8161 and HM7885. In the second cycle, the high number of leaves was maintained for the hybrids N901 and TPC26116 and the low number of leaves for CRV 8161. And improving its performance from the first to the second cycle, the hybrid HM7885 entered the group with the highest number of leaves, unlike the hybrid CVR9145, which had a good performance in the first cycle and fell to the group with the lowest number of leaves in the second cycle. Silva et al. (2006) emphasize in their study that excess solar radiation is one of the factors that can cause greater leaf senescence, limiting plant development.

Solar radiation plays a role in crop development, as it drives photosynthesis by increasing evapotranspiration, resulting in higher crop yield. In other words, increased efficiency in the use of radiation leads to gains in productivity (Yang et al., 2019), as obtained in the first

Table 1. Plant height, number of leaves, and number of branches per plant (from six assessments between transplanting and the onset of flowering) of five tomato hybrids for industrial processing, grown in two seasons (1st Season: 04/02 to 08/10/2021 and 2nd Season: 06/04 to 09/28/2021), in Abadia de Goiás-GO, Brazil.

| Evaluation | DAT | GD (ºC.dia) | Plant Height | Number of Leaves | Number of Branches | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1st season | 2nd season | 1st season | 2nd season | 1st season | 2nd season | 1st season | 2nd season | 1st season | 2nd season | |

| 1 | 6 | 6 | 11.24 | 11.82 | 7.00 Ca | 9.75 Ca | 3.10 Da | 4.10 Ea | 0.00 Ba | 0.00 Ca |

| 2 | 11 | 11 | 12.46 | 12.95 | 7.00 Ca | 11.25 Ca | 4.05 Da | 5.55 Ea | 0.00 Ba | 0.00 Ca |

| 3 | 18 | 17 | 13.09 | 9.53 | 11.10 Ca | 14.75 Ca | 5.00 Db | 9.15 Da | 0.00 Bb | 0.80 Ba |

| 4 | 25 | 24 | 11.87 | 11.96 | 16.65 Cb | 23.60 Ba | 8.55 Cb | 23.65 Ca | 0.00 Bb | 4.55 Aa |

| 5 | 30 | 32 | 11.72 | 9.72 | 26.85 Bb | 31.80 Aa | 22.60 Bb | 37.95 Ba | 5.55 Aa | 6.80 Aa |

| 6 | 37 | 35 | 10.84 | 10 | 43.10 Aa | 39.75 Aa | 45.50 Ab | 57.10 Aa | 8.15 Aa | 8.70 Aa |

| Hybrid | Plant Height | Number of Leaves | Number of Branches | |||||||

| 1st season | 2nd season | 1st season | 2nd season | 1st season | 2nd season | |||||

| CVR 8161 | 47.50 Aa | 42.80 Ab | 44.00 Bb | 51.80 Ba | 7.80 Aa | 9.00 Aa | ||||

| CVR 9145 | 39.80 Ba | 32.80 Bb | 49.50 Aa | 50.00 Ba | 7.80 Aa | 7.00 Aa | ||||

| HM 7885 | 38.00 Ba | 41.30 Aa | 41.50 Bb | 63.00 Aa | 8.00 Aa | 9.50 Aa | ||||

| N901 | 47.80 Aa | 43.30 Aa | 46.50 Ab | 58.80 Aa | 8.80 Aa | 8.80 Aa | ||||

| TPC 26116 | 42.50 Ba | 38.30 Aa | 46.00 Ab | 62.00 Aa | 8.50 Aa | 9.30 Aa | ||||

*Means followed by the same uppercase letters in columns and lowercase letters in rows do not differ significantly from each other according to Tukey's test at a 5% significance level.

Table 2. Productivity and quality of production of five tomato hybrids for industrial processing, grown in two periods (1st Season: 04/02 to 08/10/2021 and 2nd Season: 06/04 to 09/28/2021), in Abadia de Goiás-GO, Brazil.

| Total yield (t ha-1) | Commercial yield (t ha-1) | |||||

|---|---|---|---|---|---|---|

| Hybrid | 1st season | 2nd season | Average | 1st season | 2nd season | Average |

| N-901 | 127.3 Ba | 117.8 Aa | 122,5 | 121.9 Ba | 104.7 Aa | 113,3 |

| HM-7885 | 140.9 ABa | 120.1 Ab | 130,5 | 133.3 ABa | 110.1 Ab | 121,7 |

| TPC-26116 | 128.7 Ba | 119.6 Aa | 124,1 | 122.8 Ba | 110.8 Aa | 116,8 |

| CVR-8161 | 159.3 Aa | 129.8 Ab | 144,6 | 149.8 Aa | 112.9 Ab | 131,4 |

| CVR-9145 | 139.5 ABa | 116.6 Ab | 128 | 131 ABa | 104.1 Ab | 117,6 |

| Average | 139.1 | 120.7 | 129.9 | 131.8 | 108.5 | 120.1 |

| Total soluble solids (Brix°) | Pulp yield (%) | |||||

| Hybrid | 1st season | 2nd season | Average | 1st season | 2nd season | Average |

| N-901 | 4.5 Aa | 4.1 Ab | 4.3 | 18.7 Aa | 14.5 Ab | 16.6 |

| HM-7885 | 3.9 Ba | 4.0 Aa | 4 | 17.7 Aa | 15.0 Aa | 16.4 |

| TPC-26116 | 4.5 Aa | 4.5 Aa | 4.5 | 18.9 Aa | 17.0 Aa | 18.1 |

| CVR-8161 | 4.1 ABa | 4.2 Aa | 4.2 | 21.0 Aa | 16.3 Ab | 18.6 |

| CVR-9145 | 4.4 ABa | 4.4 Aa | 4.4 | 19.7 Aa | 15.4 Ab | 17.6 |

| Average | 4.3 | 4.2 | 4.3 | 19.2 | 15.6 | 17.4 |

*Means followed by the same uppercase letters in columns and lowercase letters in rows do not differ significantly from each other according to Tukey's test at a 5% probability level.

year of cultivation. Furthermore, some authors cite that its intensity has a negative effect on plant growth and development, such as reducing plant height (Lopez-Marin et al., 2011; Ilic et al., 2014; Holzman et al., 2018; Yang et al., 2019).

For the variable number of branches per plant (Table 1), in the first cycle, the presence of branches was only recorded in the fifth evaluation, showing 5.55 branches per plant, reaching 8.15 branches at the end of the vegetative phase. In the second cycle, from the third evaluation onwards, the presence of branches (0.8) was recorded, reaching 8.7 branches per plant at the end of the vegetative phase. However, for the number of branches per plant, no significant difference was observed between the two cultivation cycles, nor among the five hybrids evaluated. In general, at the end of the vegetative phase, the five hybrids presented plants with the same height and number of branches in both cultivation cycles. Although the plants presented a greater number of leaves in the second season cultivation, this was not enough to convert into greater productivity and production quality.

Table 2 presents total and commercial productivity, as well as production quality, including total soluble solids content and pulp yield.

In tomato cultivation, total productivity was higher in the first season compared to the second, reaching 139.1 and 120.7 t ha-1, respectively (Table 2). In the first season, statistical differences were observed among the hybrids. The hybrid CVR8161 stood out with a productivity of 159.3 t ha-1. The hybrids HM7885 and CVR9145 presented intermediate productivities and did not differ statistically from CVR8161, N901 and TPC26116, with yields of 140.9 and 139.5 t ha-1, respectively. In the second growing season, the hybrids did not present statistically significant differences among themselves. However, the hybrids HM7885, CVR8161 and CVR9145 showed better productivities in the first growing season, while the hybrids N901 and TPC 26116 did not present significant variations between the planting seasons.

In terms of commercial productivity, there was a difference between growing seasons, 131.8 and 108.5 t ha-1, respectively. For the first growing season, the CVR8161 hybrid once again had the highest production, with 149.8 t ha-1. Furthermore, the HM7885 and CVR9145 hybrids had statistically equal production to CVR8161, but intermediate, with 133.3 and 131.0 t ha-1, respectively. The N901 hybrid obtained a commercial productivity of 121.9 t ha-1 and the TPC26116 of 122.8 t ha-1, being the hybrids with the lowest commercial production. However, in general, commercial productivity was above the average productivity in 2021 in Goiás, which was 98 t ha-1 (Safra News, 2022). In the second year of cultivation, the hybrids did not differ from each other; however, we once again observed that the hybrids HM7885, CVR8161 and CVR9145 had higher commercial production in the first year of cultivation.

Regarding production quality (Table 2), the total soluble solids content did not vary between growing seasons, except for hybrid N901, which had a difference from the first to the second season, with 4.5 and 4.1 oBrix, respectively. Regarding the total soluble solids of the hybrids within the first season, there was a difference, with N 901 (4.5) and TPC 26116 (4.5) having the highest oBrix and HM7885 having the lowest oBrix (3.9). The other hybrids presented intermediate results. Furthermore, the hybrids had no difference in oBrix within the second season.

The number of leaves in general may not have had a positive influence on the increase in tomato productivity, but it may have influenced the quality of the fruits in the variable total soluble solids, since, comparing the quality of the average production of the two harvests between the hybrids, the hybrid TPC 26116 presented fruits with higher levels of total soluble solids compared to the hybrid HM7885. This may be related to the greater number of leaves of the hybrid TPC 26116 in relation to HM7885, in the first cycle (most productive harvest). Showing that the variable number of leaves can influence each hybrid differently, since the hybrid CRV 8161, which presented a lower number of leaves in both growing seasons, maintained high productivity and excellent production quality. Thus, hybrids that have high values of soluble solids, together with high productivity, will result in an excellent pulp yield in the factory (Soares and Rangel, 2012). Likewise, it is possible to indicate that the hybrids studied present different aptitudes for processing different products.

Regarding pulp yield, the first season showed a higher yield than the second season, with 19.2 and 15.6%, respectively. However, no statistical differences were observed between the hybrids, with an overall average of 17.4% pulp yield. For the planting seasons, the hybrids CVR 8161, CVR9145 and N901 showed differences, being the hybrids that produced more in the first season than in the second, with 21, 19.7 and 18.7% pulp yield.

The average water contents in the soil profile, in the 0.0 to 0.5 m depth layer, were 0.275 m3 m-3 and 0.255 m3 m-3, throughout the first and second growing season cycles, respectively. This reveals that there was no water restriction for any of the hybrids, throughout the two cycles, with the irrigation management adopted. Except in the last fortnight of the cycles, when the minimum average values observed were 0.21 m3 m-3, below the critical point (0.24 m3 m-3), a management adopted to favor harvesting and improve production quality. This is a common management in tomato production, cutting water 20 to 30 days before harvesting to favor ripening and the concentration of soluble solids in the fruits (Marouelli et al., 2008). It was also observed that there was no excess water, as the maximum average values were 0.32 m3 m-3 and 0.30 m3 m-3, respectively. And the moisture at average field capacity was 0.34 m3 m-3.

Materials and Methods

Plant materials

The N 901 hybrid was developed by BASF, under the Nunhems trademark, it is a tomato for processing with excellent foliage, fruits with technical maturation, high firmness, intense color, excellent brix and high productivity, its cycle is considered intermediate between 115 and 120 days, has a square shape and average weight of 70 to 80 grams per fruit, and resistance to diseases Verticillium Wilt race 1; Fusarium wilt races 1 and 2; Root-knot nematode; Bacterial Paint.

The hybrid HM 7885 has in its main characteristics high productivity, fruits with high firmness, thick walls and high cube yield in addition to good maturation concentration, with an average weight of 103 grams per fruit, in a cycle of 117 days, with brix degree between 4.5 to 5.5. It is considered a medium-sized open plant, with high resistance to Whorl Wilt and Fusariosis types 1 and 2, in addition to intermediate resistance to nematodes of the type Meloidogyne arenaria, Meloidogyne incógnita, Meloidogyne javanica.

The hybrid CVR 8161 has a cycle that varies from 120 to 140 days after transplanting, it is a large plant with good leaf coverage, the fruit is oblong with an average weight of 70 to 85 grams, the firmness aspects and the brix are classified as very good and have resistance to VFFN. As for the hybrids HM 9145 and TPC 26116, as they are pre-commercial, it is not possible to find information about their performance in the field.

Study location, climate, cultivation system and experimental arrangement

The study was carried out at the Cargill experimental station in Abadia de Goiás – GO, Brazil (49.4° W and 16.8° S, 887 m). The climate is tropical characterized by dry winter and rainy summer with an average annual temperature of 23.1 °C and average annual precipitation of 1414 mm, classified according to Köppen (Alvares et al., 2013).

Direct planting was carried out by furrowing the area at a depth of 0.15 m, in double rows spaced 0.60 x 1.20 m, with plants every 0.37 m. The seedlings were transplanted on 01/April/2021 for the 1st planting season and on 02/June/2021 for the 2nd planting season. The seedlings were 45 days old in the nursery, including five tomato hybrids for industry: TCP 26116, CVR-8161, N-901, HM-7885 and CVR-9145.

For base fertilization at planting, 273 kg ha-1 of potassium chloride, 1000 kg ha-1 of granulated MAP and 58 v of zinc sulfate were applied in the planting furrow. Topdressing fertilization was carried out via fertigation, with 31 kg ha-1 of MAP, 353 kg ha-1 of ammonium nitrate, 419 kg ha-1 of potassium chloride, 242 kg ha-1 of ammonium sulfate, 210 kg ha-1 of magnesium sulfate and 22 kg ha-1 of boric acid. In addition to fertilization, weed control and phytosanitary management were carried out according to the recommendations for the crop, following the protocol proposed by Cargill's agricultural department.

The trial was conducted in a randomized block design, in two seasons, with five hybrids and four replicates, totaling 20 experimental plots. Each plot consisted of three double planting lines of 10 m, spaced 0.6 m x 1.2 m, with plants every 0.37 m, totaling 27 plants per line and 162 plants per plot. A total of 150 plants were considered useful per plot, with the first and last plants in each line considered as borders. A 2 m strip between blocks was used as borders for movement in the area and for installing the irrigation system.

The conventional sprinkler irrigation system was installed in the area with impact sprinklers (Implebrás / IM35 / 4.0 x 2.5 mm / 35 mca / 1.7 m3 h-1 / 11.8 mm h-1, 80% efficiency) spaced 12 x 12 m, between sprinklers in the lateral irrigation line, and between lateral lines, respectively.

Irrigation was performed using the IrrigaTomate software (www.irrigatomate.com.br), which was developed for industrial tomato crops in the state of Goiás (Alves Jr., 2022). The reference evapotranspiration (ETo) calculated by the software uses the Penman Monteith method (Allen et al., 1998) from the automatic meteorological station (Metos®), installed in Hidrolândia-GO, located in the same climatic microregion. And to complete any missing data, the software uses the climate database available from InfoClima® from the study carried out by Xavier et al. (2016). IrrigaTomate uses crop coefficients (Kc) recommended by Embrapa Hortaliças (Marouelli et al., 2012) as detailed in Table 1. To calculate the gross irrigation depth, the water application efficiency (EA) of 80% was considered.

Characterization and monitoring of soil water content

The soil classification was Dystrophic Red Latosol (EMBRAPA, 2006). Soil analysis before planting, in the 0.0 to 0.4 m layer, showed the following chemical characteristics: pH (CaCl2 ) = 5.9; OM = 24.0 g dm-3; P (Mehlich) = 3.05 mg dm-3 ; Al = 0.0 mmolc dm-3 ; H+Al = 2.55 cmolc dm-3 ; K = 88.1 mg dm-3 ; Ca = 2.7 cmolc dm-3 ; Mg = 0.7 cmolc dm-3 ; CEC = 5.52 cmolc dm-3 ; V (%) = 53.66%; and the following physical characteristics: Sand = 55%; Silt = 9.5% and Clay = 35.5% (loamy-sandy texture); with estimated water retention of 1.5 mm cm-1.

Sensor sets were installed in each plot to monitor soil water content and irrigation depth throughout the tomato cycles. Each set contained a Decagon ECRN-50 rain gauge and three EC-5 sensors at depths of 0.1, 0.3, and 0.5 m in the center of the plot, connected to the Decagon EM50 data logger with readings every 20 min. The sensors were calibrated according to Sena (2021).

Biometric analysis of plants and tomato production

To monitor the biometrics of the plants, 10 plants were randomly selected from each plot, where weekly readings of the plant height were taken using a tape measure and the number of leaves and branches were counted. At the end of the cycle, total productivity, commercial productivity, total soluble solids (degree brix) and pulp yield were evaluated according to the industry criteria and requirements.

Weather monitoring

Data on incident global solar radiation, air temperature (minimum, average and maximum), relative humidity, wind speed, reference evapotranspiration and rainfall were obtained from an automatic weather station (Irriplus 5000), installed 50 meters away from the cultivation area.

To estimate crop evapotranspiration, the crop coefficient (Kc) values recommended by Embrapa (Marouelli et al., 2012) were used. The effective depth of the crop root system was defined according to Marouelli and Silva (2002), for each phenological stage.

Data analysis

After all the evaluations and tabulated data, all the assumptions of normality and linearity were tested. The data obtained were subjected to analysis of variance using the F test, using the SAS “Statistical Analysis System” program (SAS Institute, 2000), and the means were compared with each other using the Tukey test, at a 5% probability of error level.

Conclusion

The five hybrids showed better responses in the first growing season, presenting higher total productivity, commercial productivity, total soluble solids and tomato pulp yield compared to the second season, being 18.37%, 23.26%, 0.08 and 3.59% higher, respectively.

The CVR 8161 hybrid had higher total productivity, commercial productivity and higher pulp yield, in addition to the Brix degree being in the ideal range according to the proposed management.

The recommendation and management of irrigation for tomato crops for industrial processing is independent of the hybrid.

Acknowledgments

Thanks to the company Cargill for the experimental area and to the Cerrado Climate and Water Resources Research Groupe from Federal University of Goiás, for their collaboration in data collection.

References

Alves Jr J, Sena CCR, Domingos MVH, Knapp FM, Almeida FP, Casaroli D, Evangelista AWP (2021) Diagnosis of Irrigation Management in the Industrial Tomato Crop in Goiás, Brazil. Chem. Eng. Trans. 87 (1) 415-420.

Alves Jr J, Narciso MG, Silveira PM, Heinemann AB, Bezerra RS, Battisti R, Evangelista, AWP, Casaroli D, Santos JCC, Knapp FM (2022) Software para manejo da irrigação na cultura do tomate para processamento industrial em Goiás. In: Ciências Agrárias: O avanço da ciência no Brasil 5 (1) São João Del Rei: Ed. Científica Digital, 486-505.

Andriolo JL (2000) Fisiologia da produção de hortaliças em ambiente protegido. Horticultura Brasileira, 18 (1) 26-33.

Barrett DM, Weakley C, Diaz JV, Watnik M (2007) Qualitative and nutritional differences in processing tomatoes grown under commercial organic and conventional production systems. Journal of Food Science, 72 (1) 441-451.

Bezerra RS (2019) Épocas de cultivo, densidades de plantio e soma térmica de híbridos de tomate para processamento industrial. 55f. Tese (Doutorado em Agronomia) – Universidade Federal de Goiás, Escola de Agronomia, Goiânia.

Ilic ZS, Milenkovic L, Sunic L, Fallik E (2015) Effect of coloured shade-nets on plant leaf parameters and tomato fruit quality. Journal of the Science of Food and Agriculture, 95 (13) 2660-7.

Embrapa (2023) Tomate industrial-Sistema de Produção. Versão eletrônica. Acessado em 20 de setembro de 2023.

Filgueira FAR (2008) Novo manual de olericultura: agrotecnologia moderna na produção e comercialização de hortaliças. Viçosa: UFV. 421.

Knapp FM (2023) Respostas da cultura do tomate para processamento industrial a fatores ambientais e irrigação. 89f. Tese (Doutorado em Agronomia) – Universidade Federal de Goiás, Escola de Agronomia, Goiânia.

Knapp FM, Alves Jr J, Battisti R, Almeida FP, Bezerra RS, Casaroli D, Evangelista AWP, Santos JCC (2024) Environmental factors affecting tomato growth for industrial processing in the Brazilian Savannah of Goiás State. Acta Scientiarum Agronomy, 46 (1) e68354.

Jacinto LU, Soares BB, Rangel R, Jacinto AFVU (2012) Transplantio e colheita mecanizada. In: Clemente FMVT, Boiteux LS (eds.) Produção de tomate para processamento industrial. Brasília: Embrapa (14) 314-327.

Madeira NR, Silva PP, Nascimento WM (2016) Cuidados no transplante de mudas. In: Nascimento WM, Pereira RB. Produção de mudas de hortaliças. Brasília: Embrapa (1) 8, 177-194.

Marouelli WA, Silva W L C, Silva HR, Braga MB (2012) Irrigação e fertirrigação. In: Clemente FMVT, Boiteux LS. Produção de tomate para processamento industrial. Brasília, Embrapa, 344.

Papadopoulos AP, Hao X (1997) Effects of three greenhouse cover materials on tomato growth, productivity, and energy use. Scientia Horticulturae, 69 (1) 01-29.

Sales DLA (2016) Evapotranspiração e coeficiente de cultura do tomateiro industrial estimado por sensoriamento utilizando o algoritmo Safer. 65f. Dissertação (Mestrado em Agronomia) – Universidade Federal de Goiás, Escola de Agronomia, Goiânia.

SAS Institute (2000) SAS/STAT User’s Guide. version 4.0.2. SAS Institute Inc; Cary NC.

Soares BB, Rangel R (2012) Aspectos industriais da cultura. In: Clemente FMVT, Boiteux LS. Produção de tomate para processamento industrial. Brasília: Embrapa Hortaliças, 331-344.