Aust J Crop Sci. 19(04):388-397 (2025) | ISSN:1835-2707

https://doi.org/10.21475/ajcs.25.19.04.p264

Planting densities and growing times of tomato cultivars for industrial processing in the climatic conditions of the Cerrado of Goiás (Brazilian Savanna)

Adão Wagner Pêgo Evangelista, José Alves Júnior*, Ricardo de Souza Bezerra, Derblai Casaroli

School of Agronomy, Department of Soil and Water, Federal University of Goiás (UFG), Zip code 74.690.900, Goiania, Goiás, Brazil

*Corresponding author: José Alves Júnior

Abstract: The tomato planting density for industrial processing is usually 30 thousand plants ha-1 in Goiás region, to any hybrids and planting times. However, this is a topic that farmers still have many doubts about it. Thus, the objective of this work was to evaluate the response of different hybrids, grown in different planting densities and growing seasons. For this, six experiments were conducted in 2017, in Abadia de Goiás, Brazil, three experiments in season 1 (April-August), and three experiments in season 2 (May-October), for three hybrids: N-901, U-2006 and CVR- 2909, and five planting densities: 20, 25, 30, 35 and 40 thousand plants ha-1, and five replications (experimental design randomized complete blocks) and the total fresh mass of the fruits was collected to determine the production per plant (kg.plant-1) and total productivity (t ha-1). There was a significant interaction between planting densities and hybrids for all production factors evaluated. The total and commercial productivity of the hybrids CVR-2909 and N-901 responded quadratically to the evaluated planting densities, and the yields presented by the U-2006 hybrid did not respond to variations in planting densities. The plants of the hybrid U-2006 are small in size with more compact growth compared to the plants of the other hybrids evaluated, which probably confers a lower leaf area index and, consequently, a lower rate of photosynthesis due to the lower interception of solar radiation. The total productivity of hybrid N-901 when cultivated in season 1 (autumn-winter) was 28.6% lower than the total productivity of cultivation in season 2 (winter-spring). The hybrid U-2006 presents the lowest productive performance among the other hybrids evaluated and its productivity does not respond to the variation in planting density between 20 thousand plants ha-1 and 40 thousand plants ha-1. The yields of the hybrids CVR-2909 and N-901 respond positively to the increase in planting density up to 40 thousand plants ha-1.

Keywords: Solanum lycopersicum L.; plant spacing; transplant dates.

Introduction

Tomatoes for industrial processing (Solanum lycopersicum L.) stand out as one of the most important products in national and global agribusiness. In 2018, global tomato production for industrial processing was 34.328 million tons, corresponding to approximately 40 million tons of processed tomatoes (Background, 2019). Brazilian production of this crop is among the ten largest, corresponding to 3.8% of world production. Among the Brazilian regions producing this crop, the Cerrado became the most important from the 1990s onwards (Vilela et al., 2012). The State of Goiás concentrates the largest production in 12,300 hectares dedicated to the cultivation of tomatoes for industrial processing, followed by the states of Minas Gerais and São Paulo (Branthôme, 2017).

In the Cerrado region of Goiás, tomato planting for industrial processing begins in February and continues until June. Harvesting normally begins in June and continues until October (Giordano and Silva, 2000). The long cultivation period is justified by the absence of impeding factors for tomato cultivation in the region's conditions. However, at the extremes of the Brazilian tomato harvest for industrial processing, restrictive factors occur that hinder production and do not allow the crop to reach its full productive and quality potential (Soares and Rangel, 2012).

The high relative humidity of the air, normally related to the frequent rains in the Cerrado region of Goiás between the months of February and early March, is considered the main climatic factor that restricts tomato cultivation in this region. In this case, phytosanitary problems occur when cultivation occurs at the beginning of the harvest. Crops transplanted later receive rain that occurs in October, reducing the quality of the fruits and making harvesting operations difficult (Giordano and Silva, 2000; Soares and Rangel, 2012).

Tomato production for industrial processing in Brazil is carried out predominantly in the dry season, therefore the crops are entirely irrigated. Crops are generally irrigated by central pivot arranged in single or double rows. The planting density used generally for all arrangements and hybrids is 30 thousand plants per hectare (Jacinto et al., 2012). The studies to determine the best arrangements and planting densities in the crop were carried out by researchers from the agribusinesses themselves. Most of these studies were based on the use of open pollinated cultivars, direct sowing in the field and two manual harvests, that is, totally different from the current production system that uses hybrid cultivars, seedling transplantation and a single mechanized harvest (Marouelli and Silva, 2009).

Planting density directly influences the production of tomato fruits for industrial processing (Ismail and Mousa, 2014). Adequate plant density optimizes the use of light, water, soil and nutrients to obtain high yields and quality of tomato fruits for industrial processing (Patanè and Saita, 2015). In general, increasing planting density reduces vegetative growth, makes earlier fruit maturation and increases fruit production per unit area, despite reducing fruit production per plant (Ismail and Mousa, 2014).

An increase in the economic productivity of most agricultural crops, especially tomatoes for industrial processing, occurs with more dense cultivation (Law-Ogbomo and Egharevba, 2009). Warner et al. (2002) showed that an approximate increase in productivity of 2 t ha-1 can compensate for the extra cost resulting from increased planting density in tomato cultivation for industrial processing. Most of the qualitative characteristics of tomato fruits do not change with variations in planting density and the effect of density in different growing seasons remains constant (Patanè and Saita, 2015).

In view of the above, it is clear that for a given region, the positioning of the best growing seasons and planting densities for a given tomato hybrid for industrial processing are certainly important phytotechnical adjustments to obtain greater productivity with this crop. Therefore, the objective of this work was to identify the best planting densities and growing times for three important tomato hybrids for industrial processing planted by agribusinesses operating in the Cerrado region of Goiás.

Results and discussion

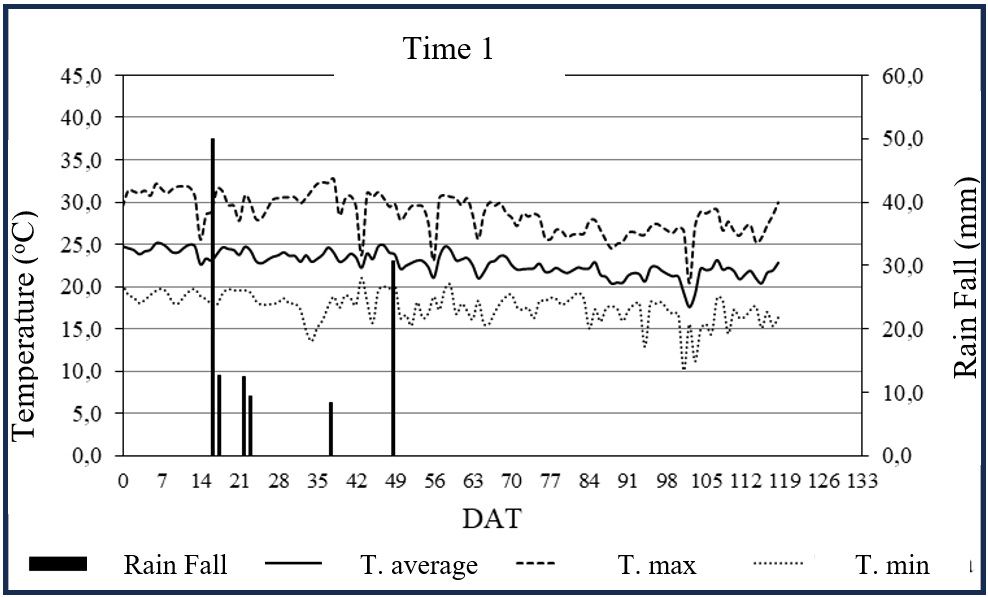

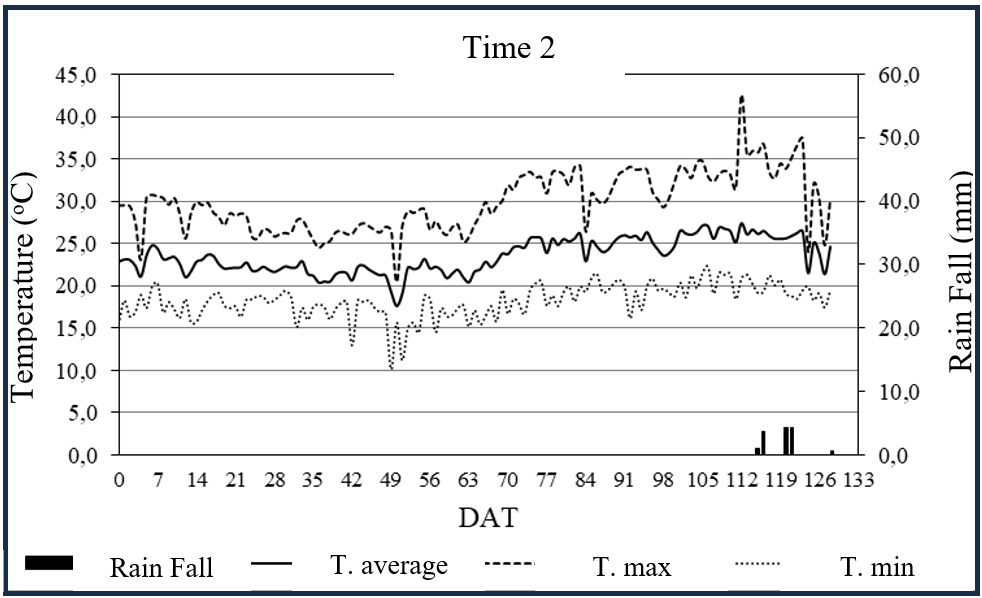

Air temperature

The daily average temperature values showed different behaviors throughout the cultivations carried out in the two seasons, with a tendency to decrease throughout the cultivation period in season 1 and an increase throughout the cultivation period in season 2 (Figures 1a and 1b). The average temperatures throughout the two cultivation periods were 22.8 °C and 23.5 °C for seasons 1 and 2, respectively, being close to the ideal average temperature for growing tomatoes for industrial processing, which is 21 °C (Giordano and Silva, 2000). The variation between daytime and nighttime temperatures were also close to the ideal range for tomato cultivation, which is between 18.5 °C and 26.5 °C (Jones, 2007).

It is noteworthy that the tomato plant is capable of tolerating a temperature range from 10 °C to 34 °C (Giordano and Silva, 2000). During the experiments, air temperatures below 18.5°C were recorded on nights during the fruiting and fruit maturation phases in season 1 and in the establishment and vegetative growth phases in season 2, however, this did not occur. air temperatures below 10°C. Air temperatures above 26.5 °C occurred during the hottest hours of the day in both crops, but records above 34 °C occurred only during the fruit maturation phase of the crop in season 2 (Figures 1a and 1b). In general, the air temperatures recorded during the experiments were within the range tolerated by the tomato crop.

Rainfall

In season 1, rainfall was concentrated until the beginning of the tomato fruiting phase, with daily values varying between 8.3 mm and 50.0 mm, at intervals of up to thirteen days, totaling a total rainfall in the period of 123 .4 mm (Figure 1a). In season 2, the total rainfall was only 14.0 mm, with rain concentrated at the end of the fruit ripening phase (Figure 1b).

The low levels of precipitation that occurred during the experiments characterize the water scarcity during the period in which the tomato harvest for industrial processing is practiced in the Cerrado region of Goiás and, therefore, makes the practical irrigation technique fundamental to guarantee the success of the culture in Brazil. According to Marouelli et al. (2012), the water demand of tomato plants in the edaphoclimatic conditions of the Cerrado can vary from 300 to 650 mm in one cycle, depending on the climatic conditions of the subregion, the cultivar and the irrigation system. Still according to this author, even when cultivation is partially carried out during the season rainy season (plantings from February to April), irrigation must be used in a supplementary manner due to insufficient volumes of rainfall and its irregularities during this period.

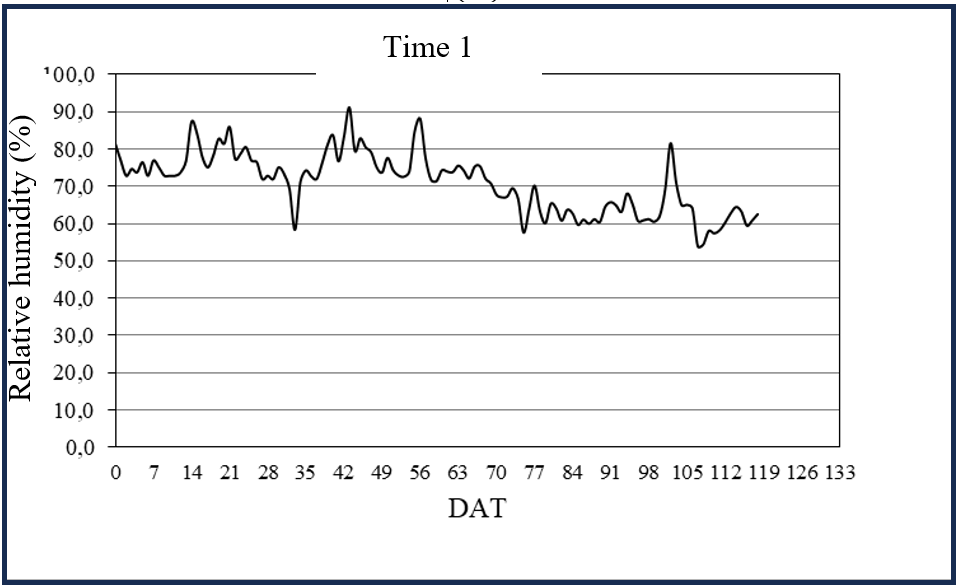

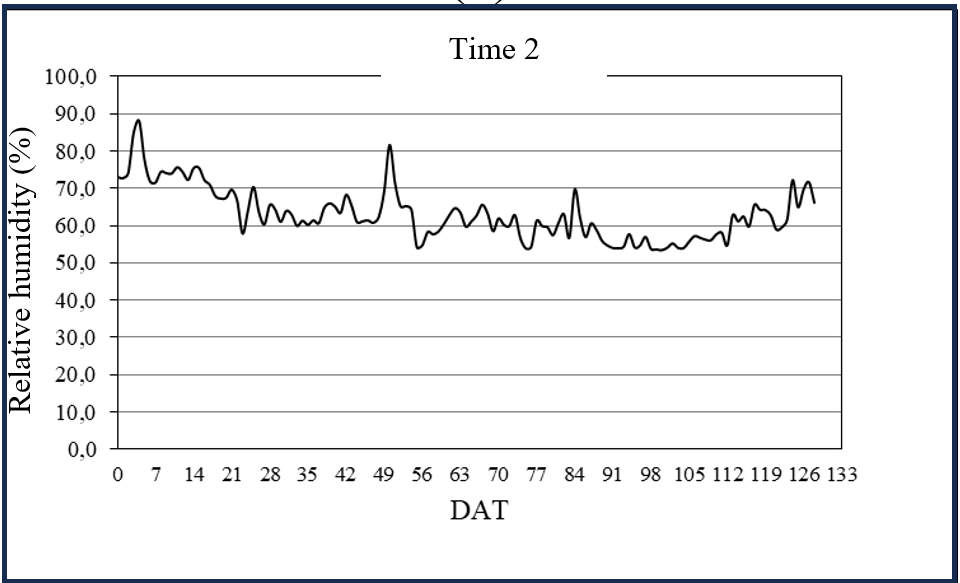

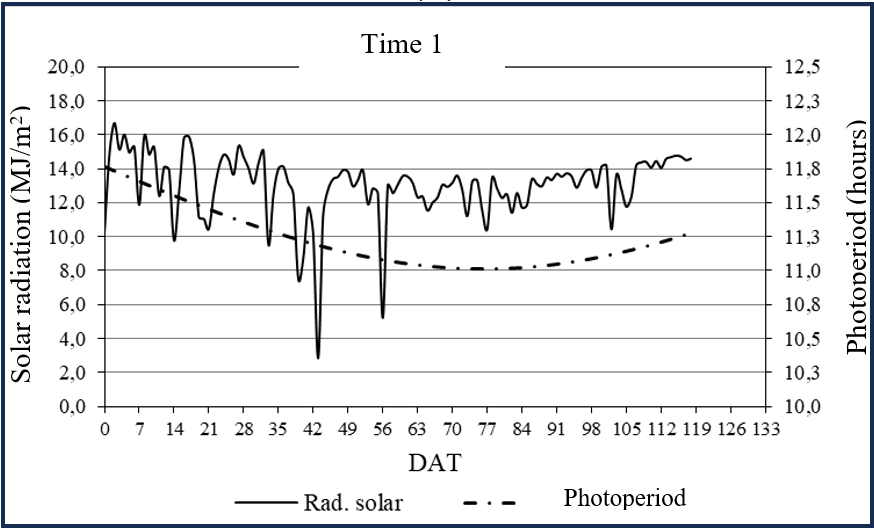

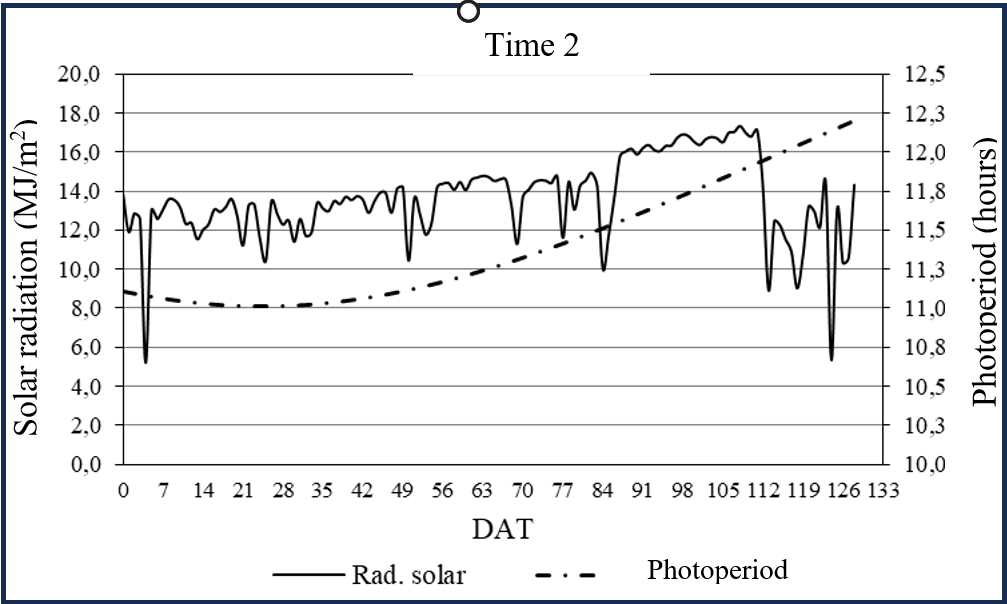

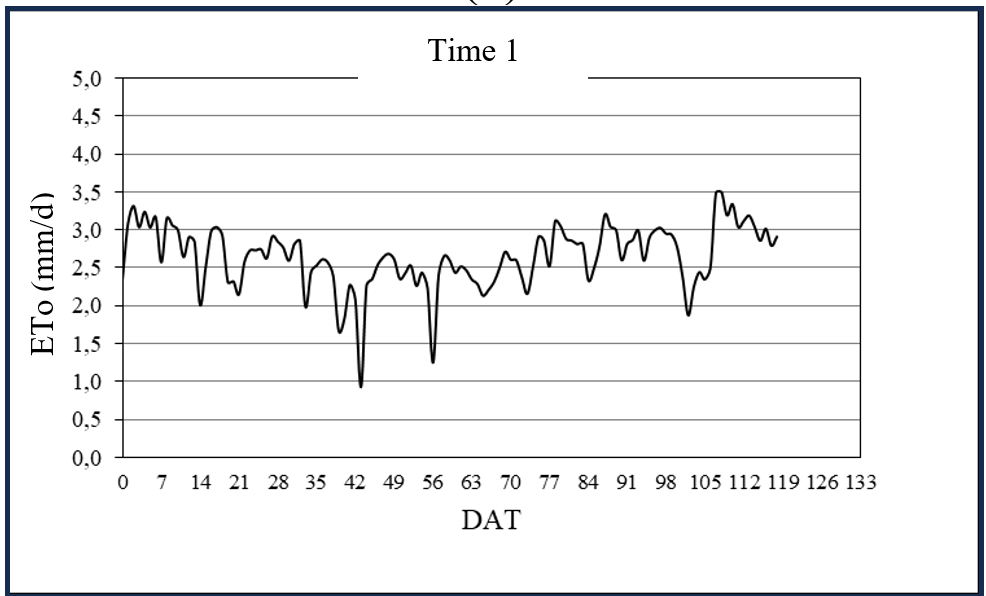

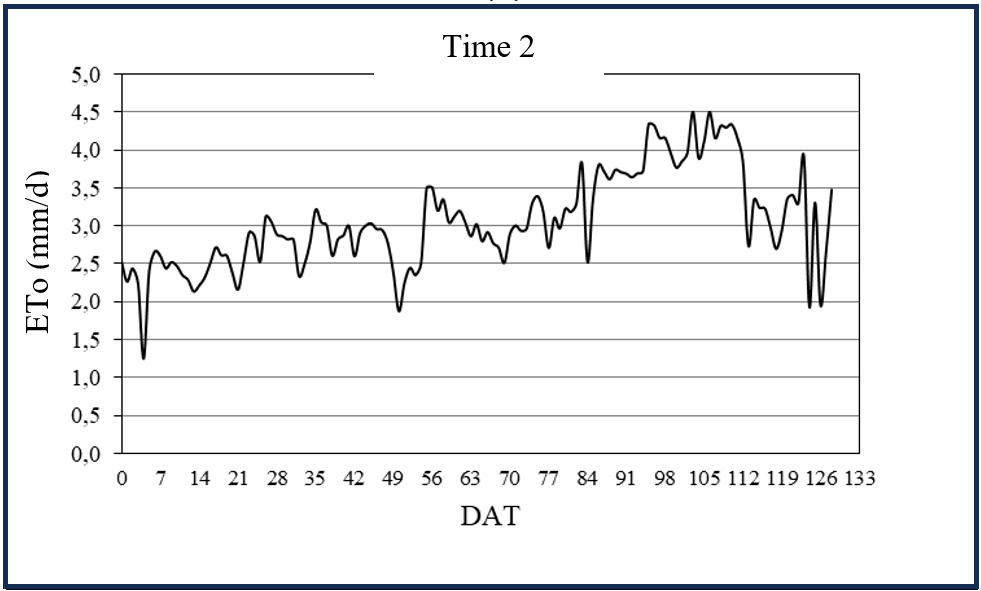

The absence of rain during cultivation justifies the decreasing trend in relative air humidity during the period (Figures 1c and 1d), whose averages were 71% and 63% in seasons 1 and 2, respectively, with a small increase at the end of season 2, due to the first rains that occurred at the beginning of the rainy season. Similar behavior was observed with daily global solar radiation, which was influenced by photoperiod and cloudiness (Figures 1e and 1f). Such behaviors highlight the strong relationship between relative air humidity and solar radiation on reference evapotranspiration (Figures 1g and 1h) and, consequently, on crop water demand, whose average values were 314 mm and 393 mm for crops from seasons 1 and 2, respectively.

Interations in planting densities, hybrids and crop seasons

There was a significant effect for the interaction between planting densities and hybrids for all production factors evaluated (Table 1). Total and commercial productivity were influenced by the interaction between hybrids and planting density. For total and commercial production, there was a significant triple interaction between hybrids, density and planting time.

Crops in season 2 showed the highest productivity and total and commercial production. Crops in season 1 were affected by foliar diseases, mainly bacterial spot (Xanthomonas sp.) and septoria (Septoria lycopersici), which occur in hot and rainy periods (Lopes et al., 2005; Csizinszky et al., 2005). These environmental conditions predominated until the beginning of the fruiting phase of crops in season 1 (Figures 1a and 1c) and are normal for

|

|

|---|---|

| (a) | (b) |

|

|

| (c) | (d) |

|

|

| (e) | (f) |

|

|

| (g) | (h) |

Figure 1. Behavior of meteorological elements recorded (A and B: Air temperature; C and D: Relative humidity, E and F: Solar radiation, G and H: Potential Evapotranspiration) over the two tomato growing seasons for industrial. processing: season 1 – April 7th to August 3rd, 2017; season 2 – May 29th to October 4th, 2017, Hidrolândia-GO, Brazil.

this season, favoring the occurrence of foliar diseases and consequent reductions in productivity (Giordano and Silva, 2000; Soares and Rangel, 2012), as these diseases reduce the leaf area responsible for photosynthesis (Lopes et al., 2005) and destroy flowers and fruits in formation (Lopes and Quezado-Duval, 2005).

The absence of significant interactions between density and planting times for the variables analyzed (Table 1) indicates that the best planting densities for each tomato hybrid evaluated are independent of the planting time. For temperate climate conditions, Heuvelink and Dorais (2005) point out that in crops grown in summer, tomatoes normally have a leaf area index below the ideal

(between 4 and 5), which reduces photosynthesis and, consequently, productivity and the quality. These authors suggest, at the beginning of this growing season when there are low levels of solar radiation, densifying the planting to increase the leaf area index.

However, the characteristic climatic conditions of the Cerrado that occurred in the period corresponding to the two growing seasons evaluated, did not present meteorological changes, especially in solar radiation, that justify changing the planting density for the same hybrid. This indicates that the best productive performance will be obtained when the cultivation of a given hybrid is carried out adopting the appropriate planting density and

Table 1. Main effects and interactions between hybrid factors (H), planting times (EP) and planting densities (DP) with the tomato crop for processing industrial.

| Treatment factor | Total productivity (t/ha) |

Commercial productivity (t/ha) | Total productivity (kg/plant) |

Commercial productivity (kg/plant) | |

|---|---|---|---|---|---|

| N-901 | 127.19 b | 119.38 a | 4.42 b | 4.16 a | |

| Hybrid (H) | U-2006 | 108.59 c | 102.58 b | 3.83 c | 3.62 b |

| CVR-2909 | 138.40 a | 120.75 a | 4.84 a | 4.21 a | |

| Teste F | 55.78 *** | 26.47 *** | 47.68 *** | 19.95 *** | |

| Época 1 | 115.70 b | 95.32 b | 4.06 b | 3.34 b | |

| Planting time (EP) | Época 2 | 133.75 a | 133.16 a | 4.67 a | 4.64 a |

| Teste F | 60.16 *** | 277.60 *** | 51.26 *** | 238.27 *** | |

| 20,000 | 117.99 b | 107.03 b | 5.90 a | 5.35 a | |

| 25,000 | 121.04 b | 110.66 b | 4.84 b | 4.43 b | |

Planting density (plants/ha)(DP) |

30,000 | 121.14 b | 111.58 b | 4.04 c | 3.72 c |

| 35,000 | 124.45 b | 113.81 b | 3.56 d | 3.26 d | |

| 40,000 | 139.00 a | 128.12 a | 3.48 d | 3.20 d | |

| Regression | Q ** | Q * | Q * | Q *** | |

| Interactions – test F | |||||

| H x EP | 7.24 ** | 22.60 *** | 30.48 *** | 23.69 *** | |

| H x DP | 2.99 ** | 3.21 ** | 1.64 ns | 1.61 ns | |

| EP x DP | 1.46 ns | 1.48 ns | 0.44 ns | 1.61 ns | |

| H x EP x DP | 1.90 ns | 1.46 ns | 3.37 ** | 2.81 ** | |

| CV (%) | 12.52 | 12.31 | 12.96 | 14.19 |

Means followed by the same letter, in the column, do not differ between them using the Tukey test with p ≤ 0.05. *, **, *** significance level with p ≤ 0.05; 0.01 and 0.001, respectively. ns not significant. Q quadratic regression.

in the growing season when the hybrid presents the best performance.

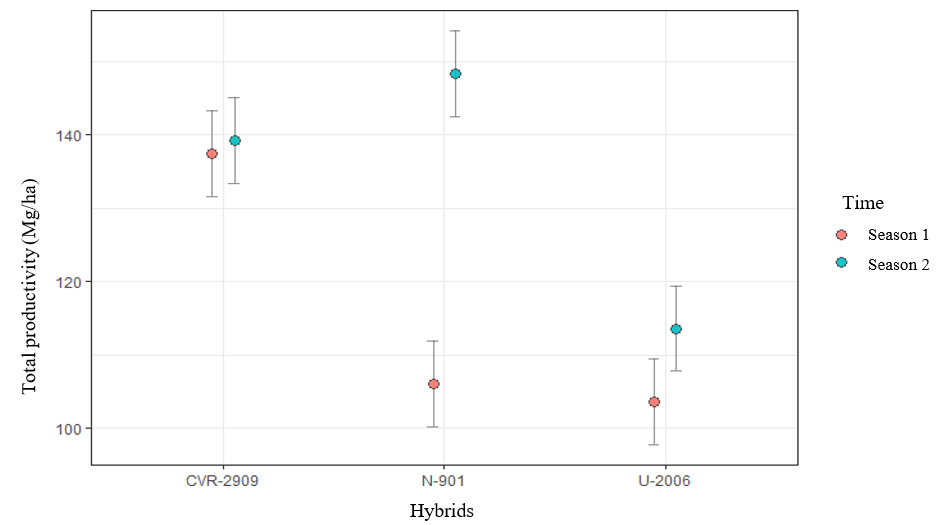

The production responses of the evaluated hybrids differed between the two planting times, which is evidenced by the significant interaction between these two factors (Table 1). The total productivity of hybrid N-901 when cultivated in season 1 was 28.6% lower than the total productivity of cultivation in season 2 (Figure 2a). This difference in the productivity of the hybrid N-901 when cultivated in the two seasons evaluated occurred, possibly due to its greater susceptibility to foliar diseases that occurred in cultivation in season 1. However, in conditions not favorable to these diseases, as was the case in cultivation in season 2, this hybrid presented a productive performance similar to the hybrid CVR- 2909 and higher to the U-2006 hybrid (Figure 2).

The CVR-2909 hybrid showed stable behavior regarding total and commercial productivity in the two planting seasons and stood out in relation to the other hybrids when cultivated in season 1. The greater adaptability of this hybrid to conditions in which the experiments were conducted can be explained by the fact that it was developed in the Cerrado's own edaphoclimatic conditions (Quezado-Duval et al., 2014). Choosing cultivars that are less susceptible to diseases, as well as positioning them at better times, is an efficient cultural practice from a phytosanitary point of view, as when associated with traditional management practices, it can reduce the indiscriminate and costly use of agricultural pesticides and avoid the emergence of resistant populations (Nascimento et al., 2013).

In crops transplanted in April (season 1), the fruit maturation uniformities of the CRV-2909, N-901 and U-2006 hybrids were, respectively, 84.2%, 93.9% and 94.5%. The high rate of green fruits recorded in the CVR-2909 hybrid indicates that the ideal cycle of this hybrid is greater than the cycle practiced in the experiment. Thus,

(a)

(b)

Figure 2. Comparation between hybrids productivity in two tomato growing seasons for industrial processing: season 1 – April 7th to August 3rd, 2017; season 2 – May 29th to October 4th, 2017, Hidrolândia-GO, Brazil. (a) total productivity and (b) commercial productivity. * Means whose bars overlap do not differ between them using the Tukey test with a significance level of 0.05.

the thermal sum of 1561.36 °C was not sufficient for the adequate ripening rate of the fruits of the CVR-2909 hybrids. Adjusting the cycle, the CVR-2909 hybrid has productive potential to be cultivated in the two seasons evaluated, since total productivity did not differ between the two seasons (Figure 2a).

The thermal accumulation of 1808.19 °C, recorded in the experiments of season 2 (Table 3), provided fruit maturation above 99% for the three hybrids. Pathak and Stoddard (2018) found accumulated degree days of 1214 °C for the ideal cycle of the five industrial processing tomato hybrids most grown in California. Differences in thermal requirements indicate different cycle lengths between cultivars. For tomato production for industrial processing in the Cerrado region of Goiás, hybrids N-901, U-2006 and CVR-2909 are considered to have medium to long cycles (Soares and Rangel, 2012).

To obtain higher quality and maximum pulp yield, the ideal is for the fruits to be all ripe and intact (Saltveit, 2005), however, the industry's continuous need for raw material and/or the occurrence of possible factors that delay the maturation of fruits in the field, as well as excess nitrogen fertilization and soil moisture (Moretti et al., 2000) justify the frequent harvests still with high rates of green fruits. In these cases, the degree-days accumulated until harvest vary in relation to the thermal requirement of the hybrid under normal growing conditions for the ideal point of fruit maturation. To avoid losses in industrial yield, when the crop has a high rate of green fruits, tomato harvesters must use the device called electronic selector, which identifies the harvested green fruits using infrared light and discards them (Soares and Rangel, 2012).

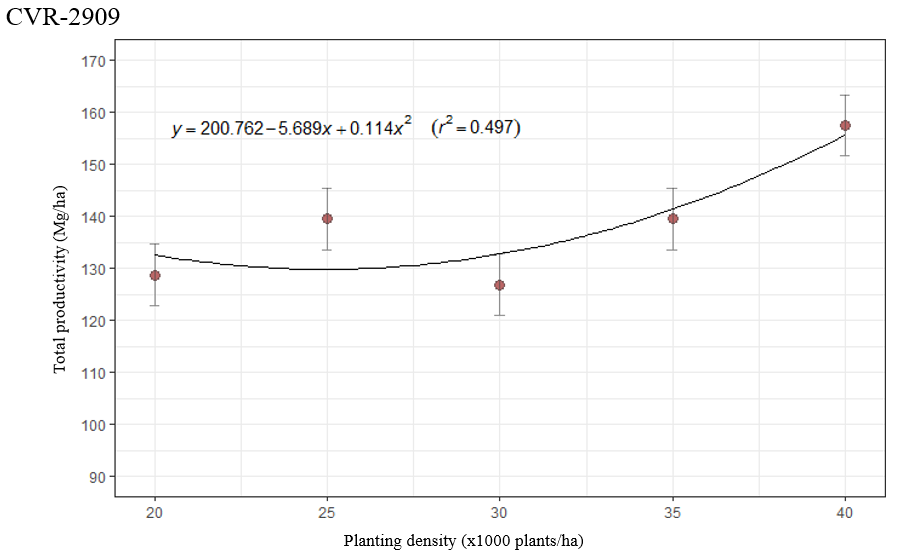

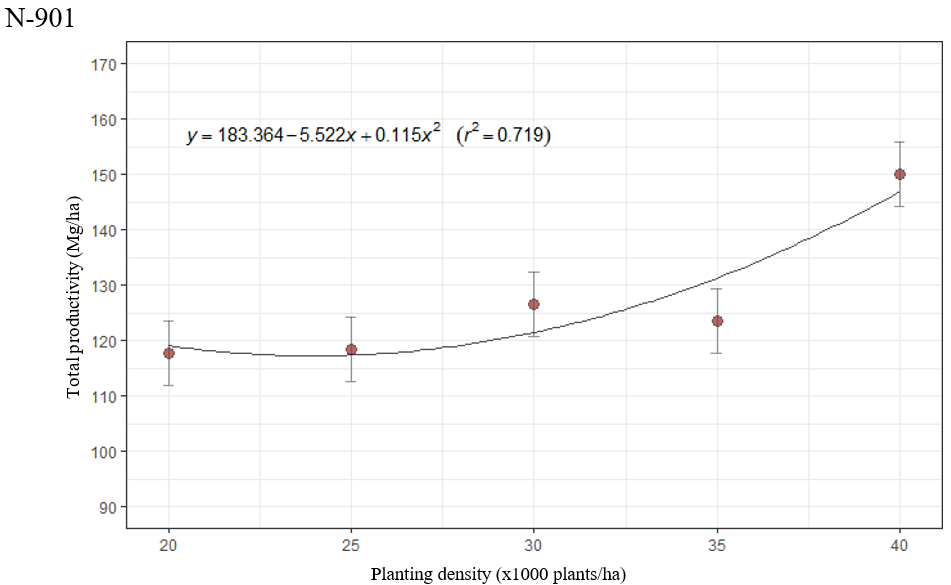

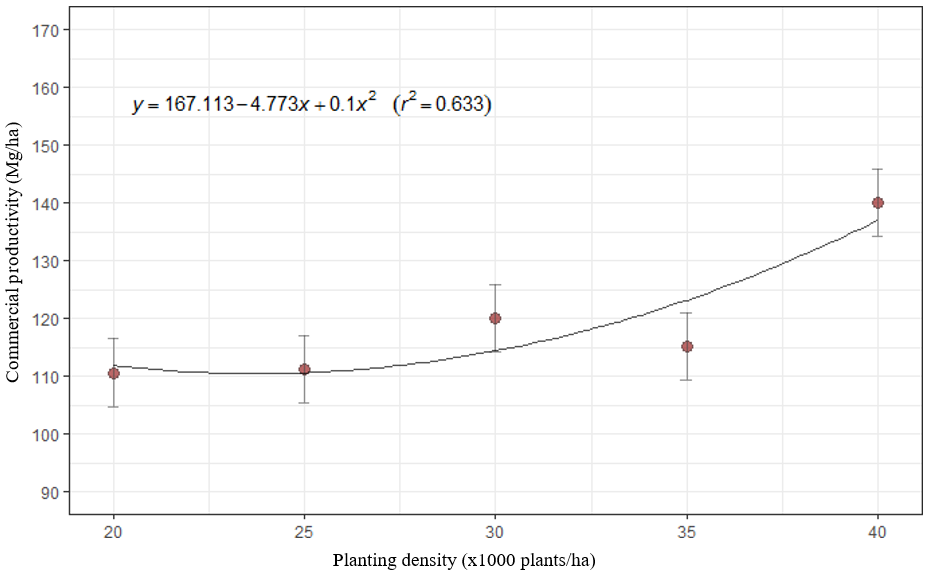

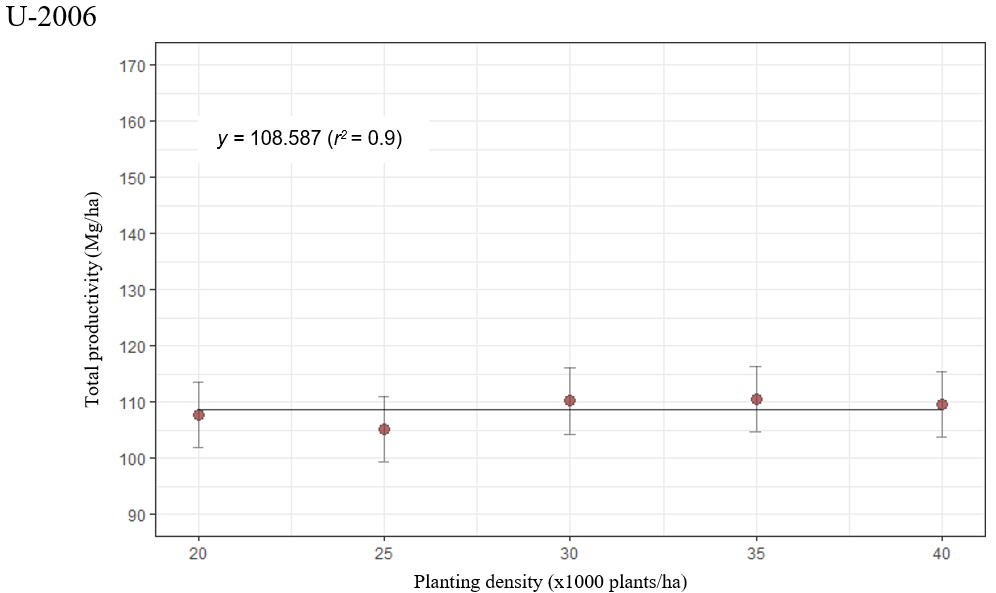

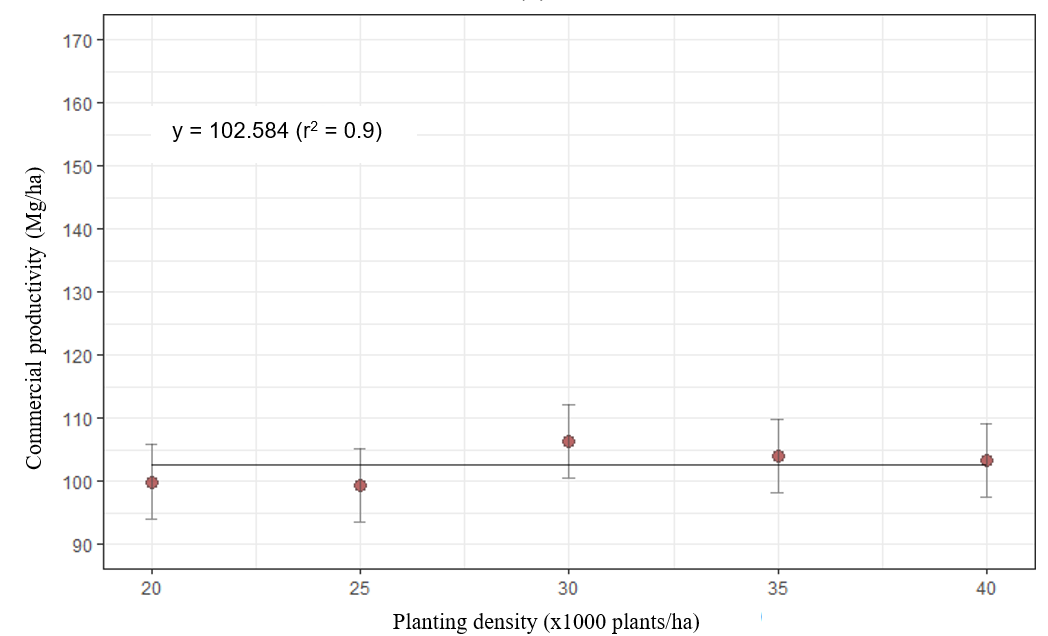

The effect of planting densities on total and commercial productivity can be visualized graphically in Figure 3. The results suggest that planting densities greater than 40,000 plants ha-1, in simple lines, should also be evaluated, as it was not possible to obtain the maximum productivity points with the evaluated densities.

The total and commercial productivity of the hybrids CVR-2909 and N-901 responded quadratically to the evaluated planting densities (Figures 4 and 5). The yields presented by the U-2006 hybrid did not respond to variations in planting densities (Figure 6). These observations reveal that tomato hybrids respond differently to variations in planting densities, reinforcing the importance of establishing the best planting density for each hybrid. The plants of the hybrid U-2006 are small in size with more compact growth compared to the plants of the other hybrids evaluated, which probably confers a lower leaf area index and, consequently, a lower rate of photosynthesis due to the lower interception of solar radiation (Heuvelink and Dorais, 2005). Still according to these authors, it is necessary for the tomato plant to reach a leaf area index between 4 and 5 for optimal light interception and best productivity. Probably, the planting densities evaluated in this work were not sufficient to cause significant changes in the leaf area index of the U-2006 hybrid plants that would justify changes in their productive performance.

Although no variations in phytosanitary conditions were observed between plants cultivated with different planting densities, increasing density tends to increase total biomass per area (Patanè and Saita, 2015). This increase in biomass can favor the incidence of foliar

| (a) |

|

| (b) |

Figure 3. Variation in total (a) and commercial (b) productivity as a function of planting density in three tomato hybrids for industrial processing grown in Hidrolândia-GO, Brazil. * Means whose bars overlap do not differ between them using the Tukey test with a significance level of 0.05.

diseases and rot due to the formation of a very humid environment in the plant canopy (Quezado-Duval and Lopes, 2012) in addition to reducing the efficiency of pesticide application due to greater difficulty in penetrating the drops in the plant canopy (Heuvelink and Dorais, 2000).

Taking into account the phytosanitary aspects of plantings made at the beginning of the harvest, which receive rain and favor the appearance of bacterioses, Giordano and Silva (2000) suggest reducing planting density as a strategy for controlling these diseases. On the other hand, denser plantings tend to reduce fruit losses due to scalding, as they tend to protect the fruits more against the direct impacts of solar radiation (Patanè and Saita, 2015; Law-Ogbomo and Egharevba, 2009). This observation may be important for the quality of later crops than the seasons tested in this work, as the end of the later crop cycle coincides with the time of year with strong levels of solar radiation in the Cerrado region of Goiás.

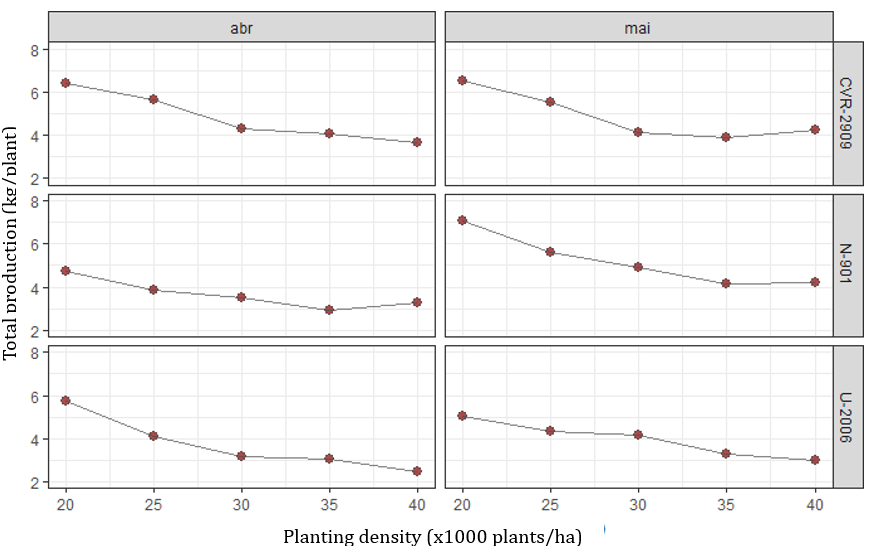

As the triple interaction between planting density, planting time and hybrid was significant for fruit production per plant (Table 1), it is necessary to evaluate each combination of these factors individually (Figure 7). Overall, the increase in planting density reduced the fruit production per plant of the three hybrids (Figure 7). This reduction probably occurred due to competition between plants for nutrients, light and water (Ismail and Mousa, 2014; Law-Ogbomo and Egharevba, 2009). According to Heuvelink and Dorais (2005), the reduction in solar radiation in the plant canopy due to the increase in planting density negatively influences the number of flowers per inflorescence and, consequently, reduces the number of fruits per plant. In denser plantings, individual plant performance is reduced, but the greater number of plants per hectare compensates for the lower individual performance and consequently increases production per area (Ismail and Mousa, 2014).

To adopt denser plantings, these advantages and possible disadvantages must be technically evaluated. Furthermore, economic analysis is of fundamental importance, as the cost of tomato seedlings for industrial processing is significant for the production of this crop. Considering the adoption of 33,000 plants ha-1 and the costs incurred in tomato production for industrial processing in the Goiânia-GO region, 2018 harvest, the cost of seeds and seedlings represented approximately 11.1% of the total production cost (Deleo and Boteon, 2018).

Materials and methods

Experimental area

The experiments were conducted during the 2017 harvest in the experimental area of the company Cargill Agrícola, located in Hidrolândia-GO, Brazil. The experiment site is located at the geographic coordinates of 16° 57’ 10” S and 49° 21’ 1.7” W, and 788 m altitude. The climate of the region, according to the Köppen classification, is type Aw (tropical with a well-defined dry season), characterized by a rainy season, between the months of October and April, in which around 90% of the total annual rainfall occurs. The soil is of the Red Oxisol type, with a sandy-clay-loam texture (Santos et al., 2018).

Experimental design

Six experiments were conducted in the 2017 harvest. Three experiments were carried out in season 1, between April 7th and August 3rd (autumn-winter), and three experiments were carried out in season 2, between May 29th and October 4th (winter-spring) one experiment for each hybrid: N-901, U-2006 (Nunhems, Netherlands) and CVR- 2909 (CVR Plant Breeding, Brazil), cultivated in five planting density (D1 = 20 thousand plants ha-1; D2 = 25 thousand plants ha-1; D3 = 30 thousand plants ha-1; D4 = 35 plants ha-1; and D5 = 40 thousand plants ha-1). The effects of planting densities in the six experiments were analyzed together, considering the three hybrids (N-901; U- 2006; and CVR-2909) and the two growing seasons (season 1; season 2) as the effects of the experiments. Each plot consisted of 3 planting lines, each 10 m long. Data collections were carried out on 10 sequential plants of the central line.

Hybrids

The U-2006 hybrid has proven tolerance to bacterial diseases, mainly bacterial spot (Nascimento et al., 2013), whose incidences restrict production in crops transplanted in rainy months (Silva and Giordano, 2000). The N-901 hybrid stands out for its high productive potential and fruit quality, such as color, firmness and good ability to remain ripe in the field waiting for harvest, “waiting capacity”. And the CVR-2909 hybrid is highly productive and has good tolerance to foliar diseases

|

|---|

| (a) |

|

| (b) |

Figure 4. Variations in total (a) and commercial (b) productivity as a function of planting density presented by the tomato hybrid CVR-2909 cultivated in the climatic conditions in Hidrolândia-GO, Brazil. * Means whose bars overlap do not differ between them using the Tukey test with a significance level of 0.05.

when grown in rainy months.

Conduction of study

Meteorological data were obtained through an automatic meteorological station located approximately 50 m from the experimental area, equipped with sensors for measuring temperature and relative air humidity, wind speed and solar radiation. Meteorological elements were recorded every fifteen minutes by a data logger (E-5000, Irriplus, Brazil). The averages of meteorological elements were also calculated for each planting season.

The seedlings were produced in trays with 450 cells and manually transplanted 30 days after sowing, with one seedling per hole. The planting arrangement was in simple rows with 1.4 m distance between rows. The distances between plants, in the row, varied from 0.179 m to 0.357 m, according to the planting density of each treatment.

Phytosanitary control was carried out weekly with fungicides and insecticides according to the presence of pests and diseases. For this, a tractor-mounted spray bar and a spray volume of 200 L ha-1 were used until 60 days after transplanting (DAT) and 370 L ha-1 after 60 DAT until harvest.

In all crops, soil preparation was conventional, with plowing at a depth of 25 cm and harrowing. Planting fertilizations were carried out in the furrows applying 1500 kg of fertilizer 04-30-16 + 0.3% Zn + 0.2% B + 0.2% Mn per hectare.

Top dressing was applied by fertigation, via a central

|

|---|

| (a) |

|

| (b) |

Figure 5. Variations in total (a) and commercial (b) productivity as a function of planting density presented by the tomato hybrid N-901 cultivated in the climatic conditions in Hidrolândia-GO, Brazil. * Means whose bars overlap do not differ between them using the Tukey test with a significance level of 0.05.

pivot, using ammonium nitrate (130 kg ha-1), ammonium sulfate (70 kg ha-1), potassium chloride (220 kg ha-1) and monoammonium. phosphate (20 kg ha-1). The fertilizations were the same for the different planting densities and totaled 117 kg ha-1, 464 kg ha-1 and 368 kg ha-1 of N, P2O5 and K20, respectively.

Irrigations were carried out using a central pivot. The water depths applied were calculated to reestablish crop evapotranspiration (ETc) according to the water balance method (ETc = ETo x Kc) proposed by Doorenbos and Pruitt (1977). Reference evapotranspiration (ETo) was estimated according to the method proposed by Penman-Monteith parameterized by FAO (Allen et al., 1998). The crop coefficients (Kc) adopted were 0.80-0.90 for the initial phase of the tomato plant (crop establishment); 0.55-0.65 for the vegetative growth phase; 1.00-1.10 for the fruiting phase; and 0.25-0.35 for the maturation phase, as proposed by Marouelli et al. (2012). Irrigations were carried out when the soil matrix tension at a depth of 20 cm, determined by tensiometers, reached -35 kPa. The degree-days accumulated during the cultivation cycle were calculated by subtracting the basal temperature of 10°C (Giordano and Silva, 2000) from the daily average temperature, according to the method proposed by Arnold (1959).

The total fresh mass of the fruits was collected to

determine the production per plant (kg. plant-1) and total productivity (t ha-1). The fresh mass of green fruits was obtained separately to calculate commercial production per plant and commercial productivity, considering only ripe fruits. Green fruits were considered to be those that were immature with more than 50% of the surface having a green color. The maturation uniformity (UM) was also calculated, which indicates the percentage of ripe fruits or commercial production (PC) in relation to total production (PT), given by (equation 1):

UM(%) = (PC/PT)*100 (1)

The analyzes of the homogeneities of the residual mean squares of the individual experiments were carried out in accordance with the recommendations of Pimentel-Gomes (2009) for the application of the joint analysis of the experiments. The main effects and interactions were compared using the Tukey test (p < 0.05) and the effects of planting densities were analyzed using regressions with a significance level of 5%.

Conclusions

Considering the cultivation of tomatoes for industrial processing in the climatic conditions of the Cerrado of Goiás, it was concluded that: i. The climatic conditions corresponding to season 2 allow for greater productivity

|

|---|

| (a) |

|

| (b) |

Figure 6. Variations in total (a) and commercial (b) productivity as a function of planting density presented by the tomato hybrid U-2006 cultivated in the climatic conditions in Hidrolândia-GO, Brazil. * Means whose bars overlap do not differ between them using the Tukey test with a significance level of p< 0.05.

Figure 7. Variation in total fruit production per plant depending on planting density, planting time, and tomato hybrid for industrial processing grown in the climatic conditions in Hidrolândia-GO, Brazil.

for the crop; ii. Better productive performances are obtained when adopting the appropriate planting density for each hybrid and cultivation at the time when the hybrid performs best; iii. the hybrid CVR-2909 can be cultivated in the two seasons evaluated, however, a longer cycle must be considered when this hybrid is cultivated in the period corresponding to season 1; iv. The hybrid N-901 presents better productive performance when cultivated in the period corresponding to season 2; v. The hybrid U-2006 presents the lowest productive performance among the other hybrids evaluated and its productivity does not respond to the variation in planting density between 20 thousand plants ha-1 and 40 thousand plants ha-1; saw. The yields of the hybrids CVR-2909 and N-901 respond positively to the increase in planting density up to 40 thousand plants ha-1. viii. Planting densities higher than 40,000 plants ha-1 and later plantings in relation to season 2 must be evaluated, as it was not possible to obtain maximum productivity points with the densities and planting times evaluated.

Acknowledgements

Thanks to the company Cargill for the experimental area and to the Cerrado Climate and Water Resources Research Center at the Federal University of Goiás for their collaboration in data collection.

Contribution of authors

Adão Wagner Pêgo Evangelista (Advisor of the doctoral thesis, research planning and discussion of results)

José Alves Júnior (Co-supervisor of the doctoral thesis, research planning and discussion of results)

Ricardo de Souza Bezerra (author of the doctoral thesis, installation, conduction and collection of field data)

Derblai Casaroli (Research collaborator, and discussion of results)

References

Allen RG, Pereira LS, Raes D, Smith M (1998) Crop evapotranspiration: Guidelines for computing crop water requirements. Rome: FAO, 300 p. (FAO. Irrigation and Drainage Paper, 56)

Arnold CY (1959) The determination and significance of the base temperature in a linear heat unit system. Proc. Amer. Soc. Hort. Sci. Alexandria, 74 (45) 430-445.

Background (2019) The global tomato processing industry. Tomato news, Avignon, 08 jan. 2019. http://www.tomatonews.com/en/background_47.html. Acesso em: 09 fev. 2019.

Branthôme FX (2017) Brazil: Goiás is the country’s main growing region. Tomato News, Avignon, 16 nov. 2017. Disponível em: http://www.tomatonews.com/en/brazil-goias-is- the-countrys-main-growing-region_2_202.html. Acesso em: 14 jul. 2018.

Csizinszky AA, Schuster DJ, Jones JB, van Lenteren JC (2005) Crop

protection. In: Heuvelink E (Ed.). Tomatoes. 1. ed. Towbridge: CABI Publishing, 199-236.

Deleo JPB, Boteon M (2018) Hortaliças: gestão sustentável. Hortifruti Brasil. Piracicaba, v. 17, n. 179, p. 6-19, jun. 2018.

Doorenbos J, Pruitt WO (1977) Guidelines for predicting crop water requeriments. Rome: FAO, 144. (FAO. Irrigation and Drainage Paper, 24).

Giordano LB, Silva JBC (2000) Clima e época de plantio. In: Silva JBC, Giordano LB (Ed.) Tomate para processamento industrial. 1. ed. Brasília: Embrapa, 18-21.

Heuvelink E, Dorais M (2005) Crop growth and yield. In: Heuvelink E (Ed.).

Tomatoes. 1. ed. Towbridge: CABI Publishing, 85-144.

Ismail SM, Mousa MAA (2014) Optimizing tomato productivity and water use efficiency using water regimes, plant density and row spacing under arid land conditions. Irrigation and Drainage, Milton, 63 (5) 640-650.

Jacinto LU, Soares BB, Rangel R, Jacinto AFVU (2012) Transplantio e

colheita mecanizada. In: Clemente FMVT, Boiteux LS (Ed.). Produção de tomate para processamento industrial. 1. ed. Brasília: Embrapa, cap. 14, 314-327.

Jones LB (2007) Tomato Plant Culture: In the Field, Greenhouse, and Home Garden. 2 ed. Boca Raton: CRC Press, 420.

Law-ogbomo KE, Egharevba RKA (2009) Effects of planting density and NPK fertilizer application on yield and yield components of tomato (Lycopersicon esculentum Mill) in forest location. World Journal of Agricultural Sciences, Dubai, 5 (2)

152-158.

Lopes CA, Quezado-Duval AM (2005) Doenças bacterianas. In: Lopes CA,

Ávila AC (Ed.). Doenças do tomateiro. 2 ed. Brasília: Embrapa Hortaliças, 53-74.

Lopes CA, Reis A, Boiteux LS (2005) Doenças fúngicas. In: Lopes CA, Ávila AC (Ed.). Doenças do tomateiro. 2 ed. Brasília: Embrapa Hortaliças, 18-51.

Marouelli WA, Silva HB (2009) Parâmetros para o manejo de irrigação por aspersão em tomateiro para processamento na Região do Cerrado. Brasília: Embrapa Hortaliças, 28. (Boletim de pesquisa e desenvolvimento).

Marouelli WA, Silva WLC, Silva HR, Braga MB (2012) Irrigação e

fertigação. In: Clemente FMVT, Boiteux LS (Ed.) Produção de tomate para processamento industrial. 1. ed. Brasília: Embrapa, cap 6, 130-154.

Moretti CL, Calbo AG, Henz GP (2000) Fisiologia e manejo pós-colheita. In: Silva JBC, Giordano LB (Ed.) Tomate para processamento industrial. 1. ed. Brasília: Embrapa, 136-143.

Nascimento AR, Fernandes PM, Borges LC, Moita AW, Quezado-Duval AM (2013) Controle químico da mancha-bacteriana do tomate para processamento industrial em campo. Horticultura Brasileira, Brasília, 31 (1) 15- 24.

Patanè C, Saita A (2015) Biomass, fruit yield, water productivity and quality response of processing tomato to plant density and deficit irrigation under a semi-arid Mediterranean climate. Crop & Pasture Science, Collingwood, 66 (2) 224-234.

Pathak TB, Stoddard CS (2018) Climate change effects on the processing tomato growing season in California using growing degree day model. Modeling Earth Systems and Environment, Cham, 4 (15) 765-775.

Pimentel-Gomes F (2009) Curso de estatística experimental. 15.ed. Piracicaba: FEALQ, 451.

Quezado-Duval AM, Lopes CA (2012) Doenças bacterianas. In: Clemente FMVT, Boiteux LS (Ed.) Produção de tomate para processamento industrial. 1. ed. Brasília: Embrapa, cap. 9, 204-222.

Quezado-Duval AM, Nascimento AR, Pontes NC, Moita AW, Assunção A, Golynski A, Inoue-Nagata AK, Oliveira RT, Castro YO, Melo BJ (2014) Desempenho de híbridos de tomate para processamento industrial em pressão de begomovirose e de mancha-bacteriana. Horticultura Brasileira, Brasília, 32 (4) 446-452.

Saltveit ME (2005) Fruit ripening and fruit quality. In: HEUVELINK, E. (Ed.). Tomatoes.

ed. Towbridge: CABI Publishing, 145-170.

Santos HG, Jacomine PKT, Anjos LHC, Oliveira VA, Lumbreras JF, Coelho MR, Almeida JA, Araujo Filho JC, Oliveira JB, CUNHA TJF (2018) Sistema brasileiro de classificação de solos. 5. ed., rev. e ampl., Brasília: Embrapa, 356.

Soares BB, Rangel R (2012) Aspectos industriais da cultura. In: Clemente, F. M. V. T.; Boiteux, L. S. (Ed.). Produção de tomate para processamento industrial. 1. ed. Brasília: Embrapa, 15, 330-344.

Vilela NJ, Melo PCT, Boiteux LS, Clemente FMVT (2012). Perfil

socioeconômico da cadeia agroindustrial no Brasil. In: Clemente FMVT, Boiteux L S (Ed.) Produção de tomate para processamento industrial. 1. ed. Brasília: Embrapa, cap. 1, 16-27.

Warner J, Hao X, Zhang T Q (2002) Effects of row arrangement and plant density on yield and quality of early, small-vined processing tomatoes. Canadian Journal of Plant Science, Ottawa, 82 (4) 765-770.